VDIS summarization

Product Description

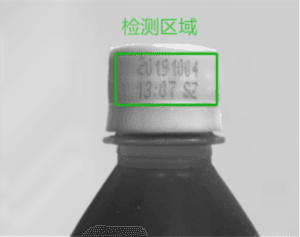

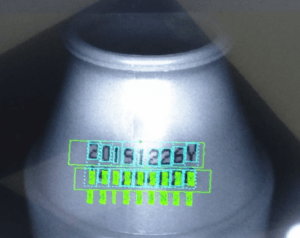

The Feature Presence Detection System (VDIS) is a state-of-the-art quality control solution designed for automated production lines. This advanced system specializes in the “presence or absence” detection of components, parts, and processing features on workpieces. With its non-contact detection capabilities, the system delivers exceptional performance, achieving high-speed inspections of up to 80,000 times per hour while maintaining superior precision.

The TST-100 model features a sophisticated 300000CCD camera resolution and LED light source configuration, enabling accurate detection across various applications. It excels in multiple inspection tasks, including code-spraying verification, cutting and drilling inspection, food label examination, package content verification, printed character detection, and electronic component presence validation on circuit boards.

This user-friendly system can be mastered within 10 minutes, offering stable performance and seamless integration with existing production equipment. It is particularly compatible with coding equipment such as inkjet printers, labeling machines, and laser systems. The system operates at impressive speeds of up to 20 pieces per second, with a visual detection range of 50-120mm, making it ideal for high-volume manufacturing environments.

The comprehensive toolset includes pattern recognition, edge detection, pixel counting, and precise measuring capabilities, supported by multiple output signals for kick-off, warning light, and stop functions. Operating under various conditions with a working temperature range of 0°C to 50°C and relative humidity of 10-90%, the system maintains reliable performance in industrial settings.

Details

Test Content

- Is there any detection of code-spraying mark

- Is there any inspection for cutting and drilling

- Is the food label inspected

- Are the instructions/accessories in the package tested

- Detection of printed characters

- Whether the electronic components on the printed circuit board are detected.

- Detection of the presence or absence of adhesive coating

- Whether the screws and gaskets of the parts are tested.

- Count the number of bottles in the carton

after sale service & Warrant

Find Support

Explore our comprehensive support services tailored for your industrial needs. We offer cutting-edge detection systems like the VDIS, designed for precision and efficiency. Click here to learn more about our advanced solutions and how they can benefit your operations.

Get product attributes and parameters

Specifications

| model | TST-100 |

| Main frequency of controller | 2.0G |

| Camera resolution | 300000CCD |

| Light source configuration | LED white can be red. |

| input signal | photosensor |

| output signal | Kick-off signal, warning light signal, stop signal |

| Detection speed | Max 20 PCs/sec |

| Detect visual detachment | 50-120mm |

| With or without communication? | Yes |

| Positioning tool | Pattern Round Edge |

| Inspection tool | Pattern Pixel count Brightness and contrast Edge |

| Measuring and counting tools | Distance Angle and Diameter Patterns and Edges |

| Power Supply | AC220V 50Hz 200W |

| Closed environment | IP62 |

| Working temperature | 0(0)C-50(0)C |

| Relative humidity (no condensation) | 10-90% |

you may want to know