material summarization

Metal UV Printing

Metal is the generally printable material for UV printers. This comes with solid intrinsic advantages. Metal UV Printing Solution is technologically advanced printing that directly cures UV light over metal substrates ink. The prints can be made high resolution and durable on stainless steel, aluminum, and iron. The cured UV ink is of highly durable quality; it is scratch- and water-resistant. It has great flexibility in printing full-color images, text, logos, and even special effects like spot UV. All this makes metal an appropriate medium for branding, signage, and custom decoration of products.

Why Choose us

Our Advantages

High-Quality Prints

Our Metal UV Printing offers high-resolution and sharp images, ensuring your designs look stunning on various metal surfaces.

Durability

The UV ink used adheres well and is resistant to fading and scratches, guaranteeing long-lasting prints.

Versatile Applications

It can be applied to custom signage, product branding, machine part labeling, decorative items, and more.

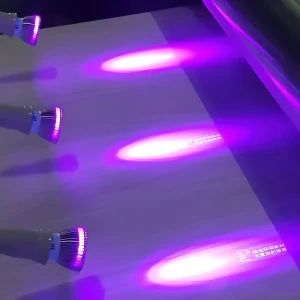

Fast Curing Process

The instant curing with UV light speeds up the printing process, saving you time.

Precision and Accuracy

Our printing technology ensures precise and accurate prints, meeting your exact specifications.

Products Can Be Used for this material

Related Products

Application Solution

Related Solutions

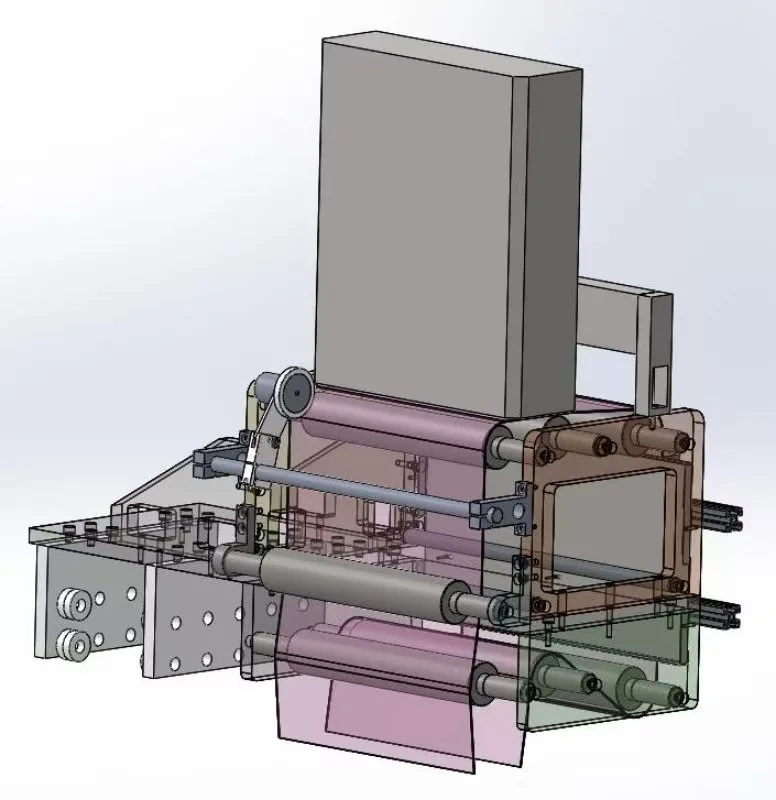

Inline UV Printing Solution

In the Inline UV printing solution, metal materials are exploited to produce high-quality and durable prints. It is direct printing on the metal surface which provides instantaneous curing with great compatibility with several substrates. This leads to a reduction in waste and higher production efficiency as printing has to be done on-demand without waiting for pre-printed materials.

Sticker

https://danmajet.com/solution/tile/UV printing on metal is a strong and durable solution for the printing of stickers, providing colors that are ultra-vivid. This process uses a UV-cured ink that adheres strongly to metal substrates, yielding a weather-resistant sticker and good durability. The process allows for the immediate drying of ink, which greatly reduces the chance for smudging and allows for an immediate application after printing.

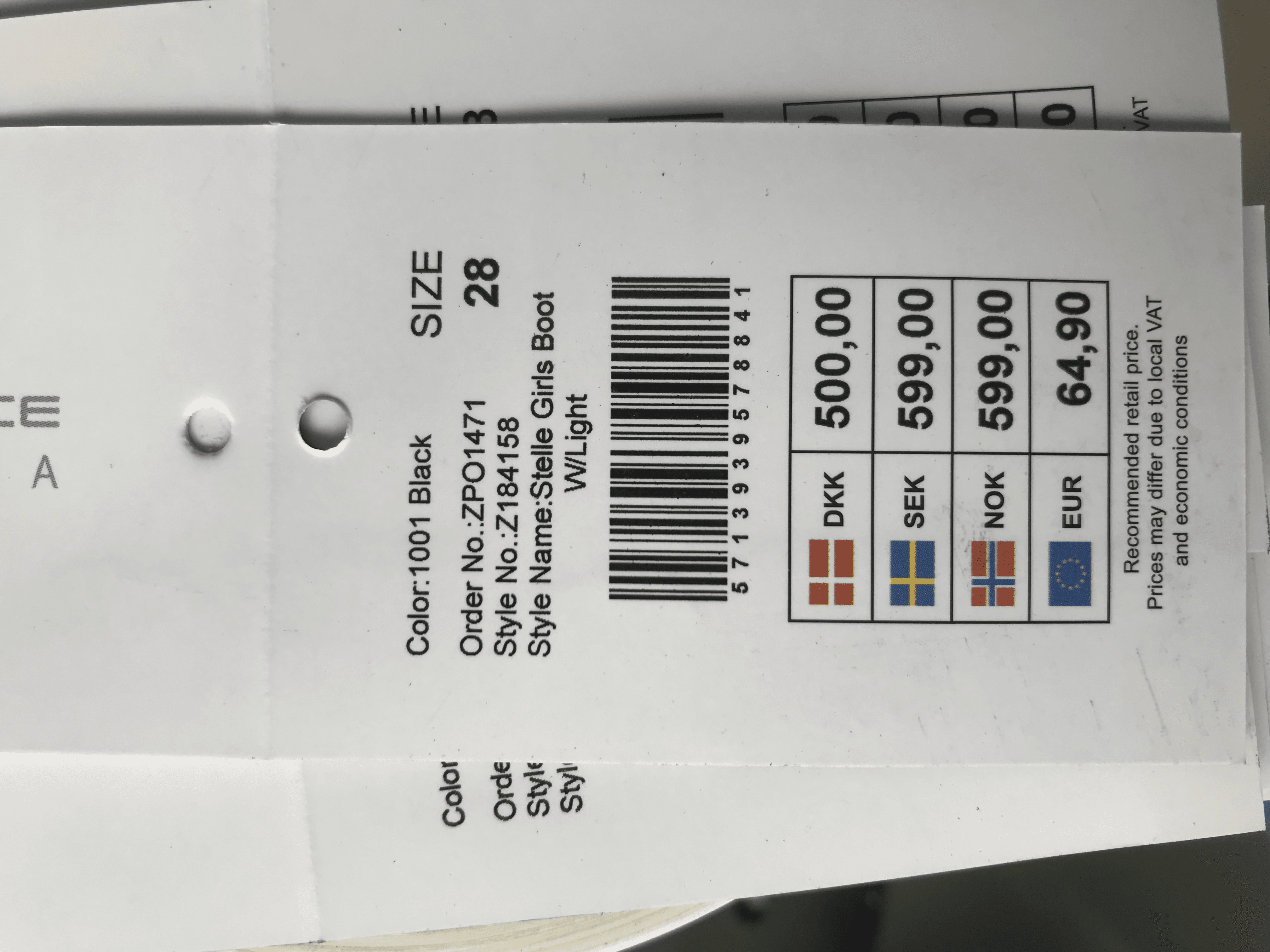

Label

Using the Metal UV Printing Solution for labels requires implementing a specialized UV printer designed for metal surfaces. This technology allows us to apply high-resolution, long-lasting inks directly onto metal labels, making sure that brands last long and are exempt from wear. UV-cured ink adheres very well and provides a very bright finish, making it great for branding and product identification.

Box

UV printing uses metal materials to produce durable and high-resolution prints for various applications of boxes. Metal is typically used in custom signs, product branding, and ornamental items on boxes, providing a strong and lasting finish.

Container Lid

Metal UV printing is applied to metal container lids in the Container Lid UV Printing Solution. This conversion process involves the use of UV light to dry the ink directly to a metallic surface: a high-resolution durable print ideal for branding and decoration.

Cup

In cup UV printing solutions, metal cups undergo pre-treatment to enhance the adhesion of ink before applying the UV ink which is cured instantly by ultraviolet light, giving durable, high-resolution prints on the metal cup surfaces.

Card

The UV production of card printing uses metals to provide durable and high-resolution printing solutions. Metal cards give a premium feel and are often used in high-end applications on membership cards and business cards. The UV ink cures very quickly to inhibit scratches and to provide durability on metal surfaces.

Tag

The process of UV Metal Printing is used in the making of durable tags that would otherwise fade and wear out. Tags made from metal using this process have the advantage of always remaining legible and bright, thus suitable for product branding, asset tracking, and safety compliance.

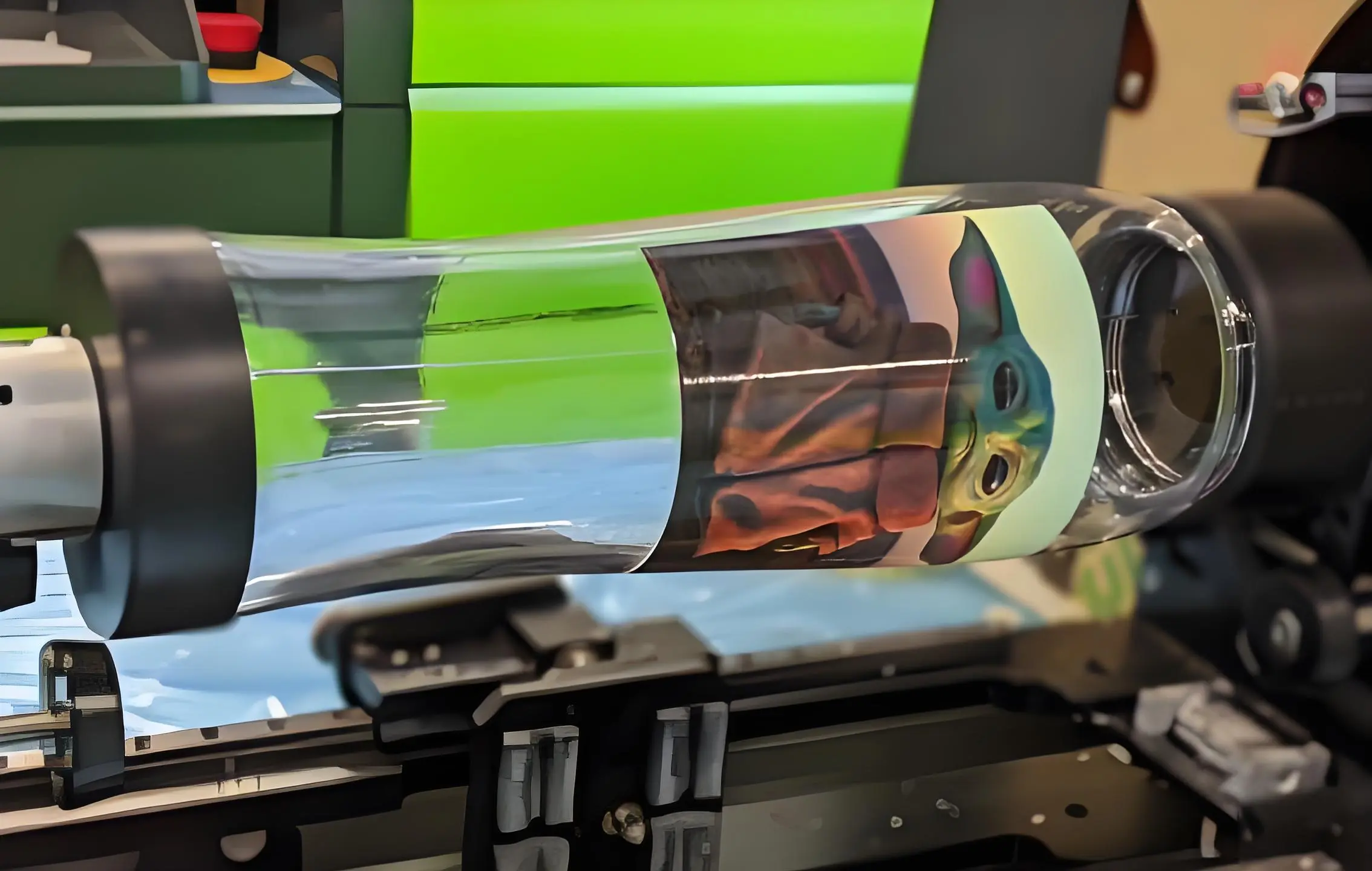

Bottle

In an effort to enhance the look and feel of bottles, UV printing on metal has been adopted. It involves UV-cured inks applied directly on the metal parts of a bottle, making designs long-lasting and resistant to little wear. This technique offers high-resolution graphics for bottle branding instead of labels that attach firmly without over-killing the product.

Wire

Wire UV printing and other metal surfaces making use of UV printable inks are generally chosen. These inks adhere well, especially to metals like copper and aluminum. The drying of the UV ink upon exposure leads to permanent and sharp printing on wires and cables.

Find Printing Content

Codes And Logo UV Printing

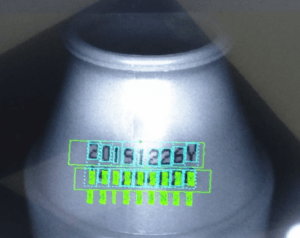

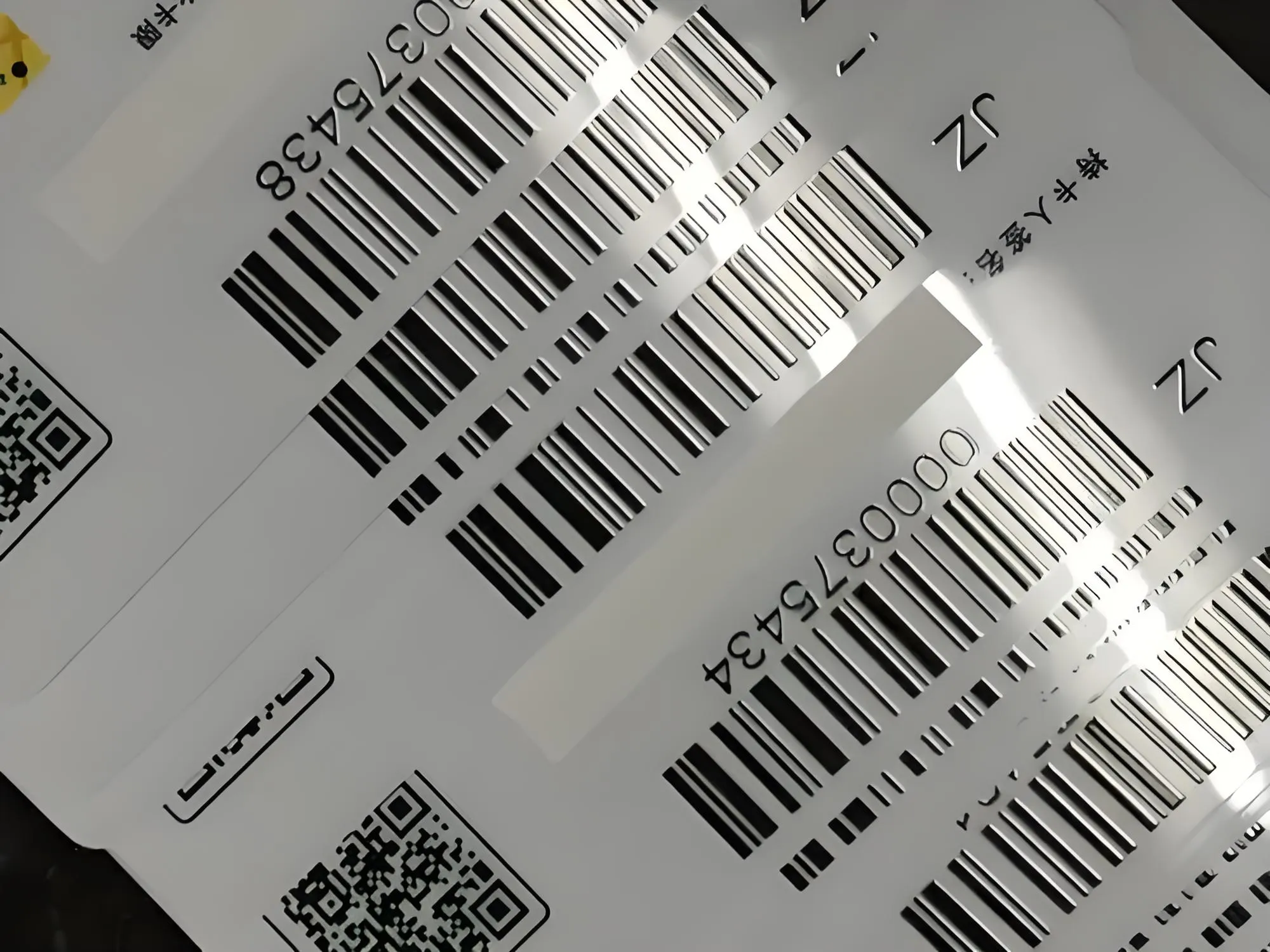

UV Printing Codes

Metal UV printing for coding amounts to applying UV ink to metal surfaces to print unique codes such as barcodes, QR codes, and serial numbers. This method ensures security and traceability through codes made invisible to the naked eye but displayed under UV light. The main features of code UV printing comprise added security against counterfeiting and diverse coding options.

UV Printing Pattern & Text

Metal UV Printing Pattern & Text involves the application of UV ink onto metal surfaces and then instant cured with ultraviolet light. This allows for high-resolution and longer-lasting prints. There is instant drying, resistance to fading and scratches, and eco-friendly because we used solvent-free inks in the process.

you may want to know