material summarization

Ceramic UV Printing

Ceramic is a well-known surface for all types of toys from tiles to coasters to tap handles. The best practice for UV printing on ceramic is indeed fast. The next advantage is that it is an environmentally friendly product as UV printers have less energy consumption, and great print quality is achieved because of low-temperature instant curing of the ink. You can also customize whatever you have in mind; thus, it would be very good for artists and designers. In short, ceramic works very well as a UV printing surface. It has all the functionality as well as endless creative possibilities.

Why Choose us

Our Advantages

Fast Production

Ceramic UV printing offers fast production. With UV printing, there are no drying times, allowing for a quicker manufacturing process.

Environmental Friendliness

UV printers use less energy as the ink is cured instantly at low temperatures, making the printing process more environmentally friendly.

Versatility

This printing technique can be used on a wide variety of materials, including ceramic, glass, wood, leather, canvas, metal, and plastics.

Customization

It allows artists and designers to create unique products for customers, fulfilling their specific needs and preferences.

High-Quality Graphics

Ceramic UV printing enables detailed images and vibrant colors on ceramic tiles, ensuring excellent visual results.

Products Can Be Used for this material

Related Products

Application Solution

Related Solutions

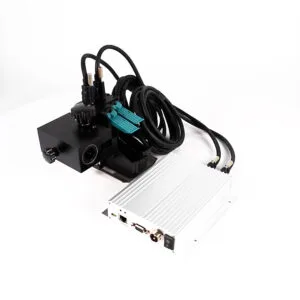

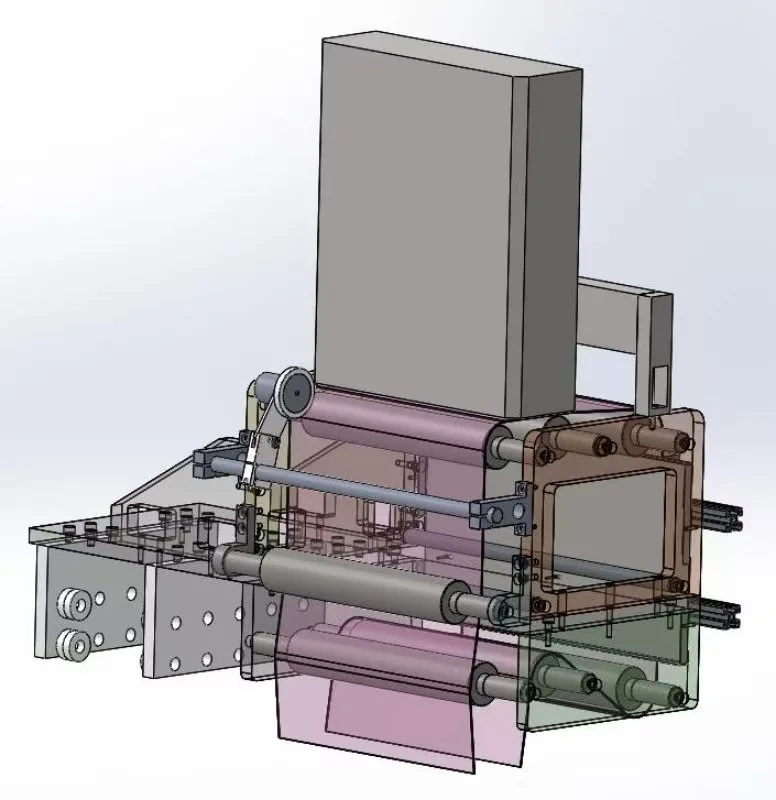

Inline UV Printing Solution

UV printing on ceramic materials is a common Inline solution for directly applying images on ceramic products like tiles and sanitary ware. This allows for the printing of high-quality and long-lasting graphics and designs capable of withstanding

Container Lid

UV printing on ceramic materials for container lids offers unique aesthetic satisfaction by combining durability with a premium look. The instant cure of ink under UV light will ensure the designs stick to the ceramic surface, enhancing the branding on a long-lasting impression.

Cup

Ceramic cups are elegant and robust, while UV placement on ceramic gives a high-resolution, vibrant finish. Print on-cup, and the instant cure of UV ink on the ceramic surface creates a dishwasher-safe and durable design.

Tile

UV printing on ceramic tiles uses special inks that are graduated UV curable and cured by ultraviolet light, resulting in high-resolution, durable, and vibrant designs. This process is suitable for making personalized decorative tiles for any application, from flooring to the wall.

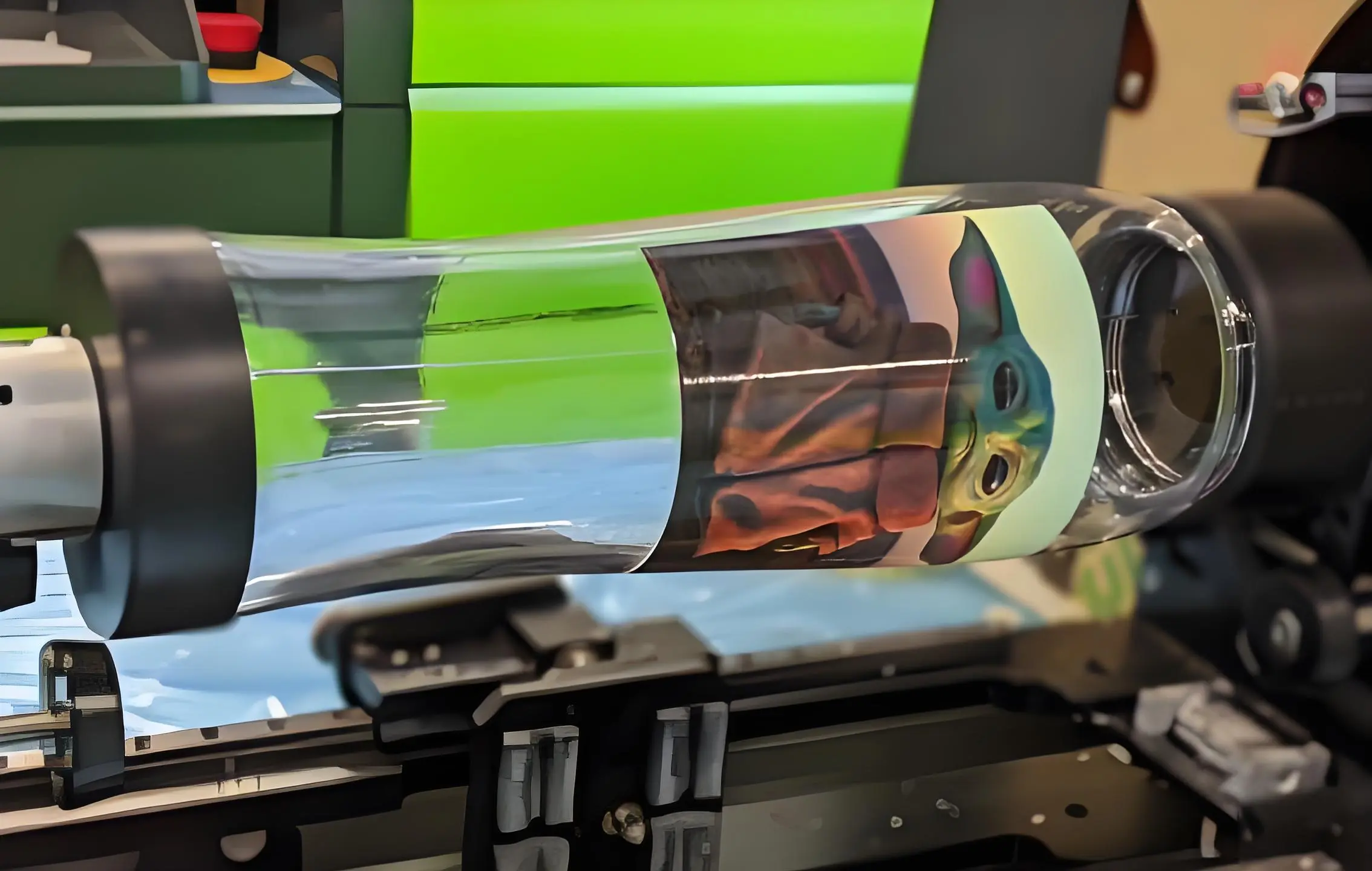

Bottle

Ceramah Ceramic UV Printing employs ceramic substances for the production of high-quality, durable prints directly on the surface of the bottle; this application facilitates the usage of intricate designs and bright colors, enhancing aesthetic appeal without the need for traditional labels.

Find Printing Content

Codes And Logo UV Printing

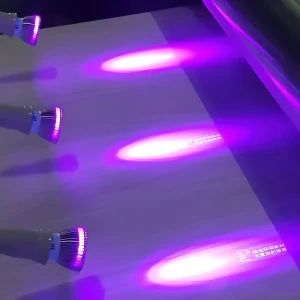

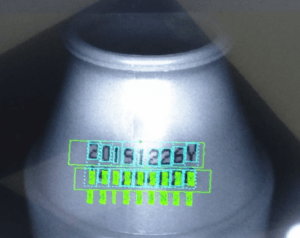

UV Printing Codes

This technique is a method of printing specific codes with ultraviolet ink to ensure security and traceability. Invisible ink used in the process is only visible under UV light; this deters counterfeiting. Main features of this include multiple coding abilities and certain inkjet printers with sensitivity to UV inks.

UV Printing Pattern & Text

A versatile means used to print patterns and texts, Ceramic UV Printing, employs ultraviolet light to cure the ink directly on the ceramic surface. It guarantees instant drying, high durability, vibrant colors, and an impressively high resolution. This is friendly to the environment since fewer pollutants are produced with less energy consumption.

you may want to know