Inkjet printing has revolutionized how industries approach design, production, and customization, particularly through various inkjet printer applications. You can see its impact in fields like fashion, where intricate fabric patterns and personalized apparel are now commonplace. In medicine, it holds the potential to create skin grafts and tissues. Automotive manufacturers use it to craft unique vehicle designs, while electronics rely on it for precise placement of conductive inks. These advancements stem from innovations like improved printhead technology and enhanced ink chemistry, which deliver sharper quality and broader inkjet printer applications. Understanding this evolution helps you appreciate its role in driving efficiency and creativity across sectors.

Key Takeaways

Inkjet printing has changed fields like fashion, medicine, and electronics.

It allows for high-quality and unique designs to be made.

New printhead tools and better inks make prints faster and stronger.

Inkjet printing costs less and works better than older methods.

It is great for small projects and custom designs.

Eco-friendly inks and green practices help protect the environment.

These methods still create excellent results.

The future includes smart inks and 3D printing ideas.

This will let inkjet printing be used in more areas.

The Historical Evolution of Inkjet Printing

Early Innovations and the Birth of Inkjet Technology

Inkjet printing began as a groundbreaking concept in the mid-20th century. Early innovations laid the foundation for the technology you see today. Key developments include:

1960s: Continuous inkjet technology emerged, with Sweet’s pioneering work leading to products like the A. B. Dick VideoJet.

1970s: IBM adapted this technology for computer printers, introducing the IBM 4640.

1979: Canon developed the drop-on-demand method using bubble jet technology, later commercialized by Hewlett-Packard in 1984 as the ThinkJet printer.

These milestones highlight how inventors and companies collaborated to transform inkjet printing from an idea into a functional technology.

Inventor/Company | Contribution/Role |

|---|---|

Howtek | Created the hot-melt color inkjet printer in 1984, led by Robert Howard. |

Exxon Office Systems | Invested in non-impact printing and recruited innovators like Ken Bower. |

Ken Bower | Established Exxon Enterprises’ engineering department, advancing inkjet research. |

Steve Zoltan | Developed on-demand inkjet technology using piezoelectric mechanisms. |

Key Milestones in Inkjet Printing Development

The evolution of inkjet printing is marked by significant milestones that shaped its trajectory. By the late 1980s, the first inkjet printers became commercially available. Siemens introduced a design in 1977 that sprayed ink only where needed, making it a consumer favorite. During the 1990s, drop-on-demand technology dominated the market, with major contributions from HP, Lexmark, and Canon.

In 1998, HP launched the HP 2000C, a pivotal innovation for business inkjet printing. Between 2000 and 2016, advancements in efficiency and features standardized inkjet printers in offices worldwide. These milestones reflect the rapid progress of inkjet technology, driven by continuous innovation.

From Niche Innovation to Industrial Adoption

Initially, inkjet printing served niche markets, but its versatility soon captured the attention of industries. The ability to print high-quality images and text on various surfaces made it indispensable. By the 1990s, businesses began adopting inkjet printers for tasks like packaging and labeling.

Today, industries such as fashion, electronics, and medicine rely on inkjet technology for precision and customization. Its journey from a specialized innovation to a widely adopted industrial tool underscores its transformative impact. You can see how this evolution has reshaped production processes across sectors.

Technological Advancements in Inkjet Printing

Breakthroughs in Printhead Design

Advancements in printhead design have significantly enhanced the performance and precision of inkjet printers. Modern printheads now feature innovative technologies that improve resolution, speed, and reliability. For instance, Hewlett-Packard’s 800 series incorporates a 192-nozzle tricolor printhead capable of jetting smaller ink droplets at an impressive rate of 12,000 drops per second. This design minimizes nozzle clogging, ensuring consistent output.

Canon’s BJC-7000 introduced a groundbreaking 480-nozzle printhead, setting a new standard for home and small office printers. This innovation improved color printing capabilities, making it ideal for high-quality image reproduction. Epson’s Color Stylus 800 printhead, with a nozzle diameter of less than 30 µm, produces ultra-fine droplets for higher resolution. These advancements demonstrate how manufacturers continue to push the boundaries of printhead technology, delivering sharper and more vibrant prints.

Enhanced Ink Chemistry for Precision and Durability

Ink chemistry has evolved to meet the demands of modern printing applications. Today’s inks are designed to deliver precision, durability, and compatibility with various substrates. Dye-based inks, for example, offer vibrant colors and smooth gradients, making them ideal for photo printing. Pigment-based inks, on the other hand, provide superior water and fade resistance, ensuring long-lasting prints.

Innovations like Canon’s P-POP technology further enhance ink performance. By applying a precoat fluid before the ink reaches the paper, this method improves waterfastness and reduces smudging. These advancements allow you to achieve professional-quality results, whether you’re printing on paper, fabric, or other materials.

System Engineering and Automation in Modern Printers

Modern inkjet printers incorporate advanced system engineering and automation to streamline operations and improve efficiency. Automated maintenance systems, for instance, reduce downtime by cleaning printheads and preventing clogs. Integrated sensors monitor ink levels and detect errors, ensuring uninterrupted printing.

High-speed processors and optimized software algorithms enable faster data processing, allowing printers to handle complex designs with ease. These features not only enhance productivity but also reduce the need for manual intervention. As a result, you can rely on inkjet printers for consistent, high-quality output across a wide range of applications.

Comparing Inkjet Printing with Traditional Methods

Inkjet printing offers unique advantages over traditional methods, making it a preferred choice for many applications. While traditional printing methods like offset or screen printing excel in high-volume production, inkjet printing provides unmatched versatility and precision. You can use inkjet printers to create high-resolution prints with vibrant colors and sharp details, rivaling the quality of offset printing. This capability makes it ideal for producing marketing materials, photographs, and even intricate designs on textiles.

One of the most significant differences lies in cost efficiency. Inkjet printing typically involves lower initial costs compared to traditional methods. For example:

Printing Method | Initial Costs | Ongoing Material Expenses |

|---|---|---|

Handheld Inkjet Printers | Lower | Lower |

Traditional Methods | Higher | Higher |

Handheld inkjet printers also provide excellent mobility and efficiency, allowing you to print on diverse surfaces. Traditional methods, however, remain advantageous for large-scale production due to their speed and durability.

Inkjet printing stands out for its ability to print on various substrates, including paper, fabric, ceramics, and even metal. This versatility enables you to explore creative applications across industries. Additionally, inkjet technology supports variable data printing, which allows for personalized content such as customized labels or direct mail campaigns. Traditional methods often lack this level of flexibility, making inkjet printing a more dynamic solution for modern needs.

Tip: If you prioritize customization and precision over bulk production, inkjet printing is the better choice. It adapts to your specific requirements without compromising quality.

By combining efficiency, adaptability, and high-quality output, inkjet printing continues to redefine what’s possible in the world of printing. Whether you’re working on small-scale projects or exploring innovative applications, it offers a compelling alternative to traditional methods.

Inkjet Printer Applications in Modern Industries

Revolutionizing Fashion and Textile Printing

Inkjet printing has transformed the fashion and textile industry by enabling innovative techniques and improving production efficiency. You can now achieve intricate designs directly on fabrics through Direct-to-Garment (DTG) printing. This method eliminates the need for intermediate steps, allowing for faster production and reduced labor costs. Sublimation printing, another breakthrough, transfers dye onto fabric, creating permanent and fade-resistant prints. Digital textile printing takes it a step further by delivering complex patterns with exceptional color accuracy across various materials.

Customization has become more accessible with inkjet technology. Micro-factories now use it to produce highly detailed, personalized designs. Water-based pigment inks contribute to sustainability by minimizing water usage and waste, making this approach environmentally friendly. These advancements highlight how inkjet printer applications have revolutionized the way you can create and customize textiles.

Advancements in Medical and Pharmaceutical Printing

Inkjet printing is reshaping medical and pharmaceutical fields by enabling precise and personalized solutions. You can now produce medications tailored to individual needs, adjusting dosages and drug release rates with remarkable accuracy. This technology also supports the creation of 3D-printed tablets that combine multiple medications into a single dose, improving patient compliance and convenience.

Beyond tablets, inkjet printing is being explored for innovative drug delivery systems. Transdermal patches and buccal films, for instance, allow direct drug absorption into the bloodstream, bypassing the digestive system. These advancements demonstrate how inkjet printer applications are driving progress in healthcare, offering you more efficient and patient-centric solutions.

Electronics Manufacturing and Circuit Printing

In electronics manufacturing, inkjet printing provides unmatched precision and versatility. You can use it to create detailed microstructures in electrodes, essential for advanced electronic devices. This method reduces material waste compared to traditional techniques, making it a cost-effective and sustainable option.

Inkjet technology also enables the production of larger electrodes with enhanced energy storage and power density. Its adaptability allows you to explore diverse applications, from flexible circuits to wearable electronics. These innovations underscore the critical role of inkjet printer applications in advancing modern electronics, offering you efficient and precise manufacturing solutions.

Packaging and Labeling Innovations

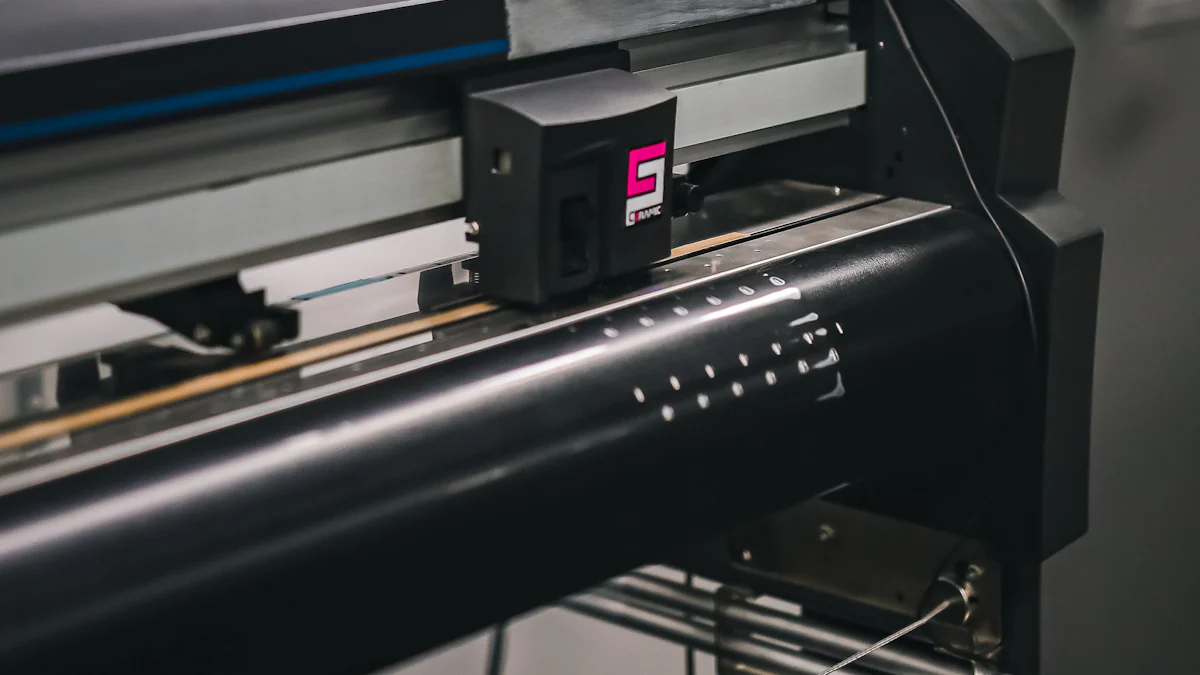

Inkjet printing has brought transformative changes to the packaging and labeling industries. You can now achieve faster production cycles and greater design flexibility, making it a preferred choice for businesses aiming to stand out. Unlike traditional methods, inkjet technology eliminates the need for printing plates, reducing waste and emissions. This direct-to-medium approach minimizes extra materials, offering an efficient and environmentally friendly solution.

Industry experts like Jim Williams, vice president of sales and marketing at Kirk-Rudy, describe inkjet technology as revolutionary for packaging. Sean Smyth, a print analyst, highlights its high value-add opportunities, which drive converters to explore digital options. Although digital printing currently covers only about 2% of the total packaging market, nearly 73% of converters view it as disruptive and transformational for the future. Market research predicts that digital printing will be the fastest-growing technology for packaging between 2022 and 2027.

Inkjet printer applications in packaging allow you to create vibrant, high-resolution designs on various materials, including cardboard, plastic, and metal. This versatility supports the production of personalized labels, limited-edition packaging, and promotional materials. By adopting inkjet technology, you can enhance your brand’s visual appeal while reducing environmental impact.

Artistic and Customization Opportunities

Inkjet printing is more than a reproduction tool; it serves as a creative medium for artists and designers. You can manipulate digital images to produce unique outputs, transforming your artistic vision into reality. This process-oriented approach expands creative possibilities, making inkjet printing a valuable asset for customized creations.

With inkjet printer applications, you can produce high-quality prints of photographs, paintings, and other artistic works. Designers benefit from accurate color representation, enabling detailed reproductions of their creations. In home decor, inkjet technology allows you to personalize products like wallpaper and decorative laminates, adding a unique touch to any space.

The ability to customize extends beyond art. Businesses use inkjet printing to create tailored marketing materials, such as branded merchandise and promotional items. This adaptability ensures that your designs remain distinctive and aligned with your vision. Whether you’re an artist, designer, or entrepreneur, inkjet printing empowers you to explore new creative horizons.

Sustainability in Inkjet Printing

Eco-Friendly Inks and Sustainable Materials

Inkjet printing has embraced sustainability by adopting eco-friendly inks and materials. You can now choose from a range of inks that reduce environmental impact while maintaining high-quality results. Algae-based ink stands out as the most sustainable option, offering a negative carbon footprint. It biodegrades quickly, making it safer for the environment and easier to handle.

Other eco-friendly inks include:

Water-Based Ink: Uses water as a carrier, reducing harmful volatile organic compound (VOC) emissions.

Soy-Based Ink: Made from soybean oil, it delivers vibrant colors with minimal VOCs.

Latex Ink: Known for durability and low VOC content, ideal for large-format printing.

UV-Curable Ink: Cured with UV light, it minimizes waste but requires more energy.

You can also explore bio-based mineral-oil-free (MOF) inks, which are compostable and nearly VOC-free. These options demonstrate how inkjet printing aligns with sustainable practices, offering you environmentally responsible choices without compromising performance.

Minimizing Waste and Energy Consumption

Inkjet technology helps you reduce waste and energy use through innovative processes. Unlike traditional printing methods, inkjet printing applies ink directly to the substrate, eliminating the need for plates or excess materials. This precision minimizes overprinting and material waste.

Modern printers also feature automated systems that optimize ink usage and prevent unnecessary consumption. High-efficiency printheads reduce energy requirements by delivering precise droplets, ensuring you achieve high-quality results with minimal resources. Additionally, water-based digital inks support small production runs, reducing waste associated with large-scale printing.

By adopting these advancements, you can lower your environmental footprint while maintaining cost-effective operations.

Recycling and Circular Economy in Printing

Recycling and circular economy practices are reshaping the inkjet printing industry. You can participate in waste reduction programs that optimize material use and minimize print waste. Direct-to-object printing eliminates the need for labels, reducing unnecessary materials. Washable inks simplify the recycling of plastic films, making the process more efficient.

Sustainable inks also play a crucial role in enhancing recyclability. For example, algae-based and water-based inks break down easily, supporting eco-friendly disposal. These practices align with circular economy principles, ensuring that resources are reused and waste is minimized.

By integrating these strategies into your printing processes, you contribute to a more sustainable future while benefiting from innovative and efficient solutions.

The Future of Inkjet Printing

Emerging Trends and Innovations in Inkjet Technology

Inkjet technology continues to evolve, introducing trends that redefine its capabilities. You can now explore eco-friendly inks, such as plant-based and solvent-free options, which reduce environmental impact while maintaining high-quality output. Smart ink technology is another innovation, integrating IoT to monitor ink levels and optimize distribution. This advancement enhances efficiency and minimizes waste.

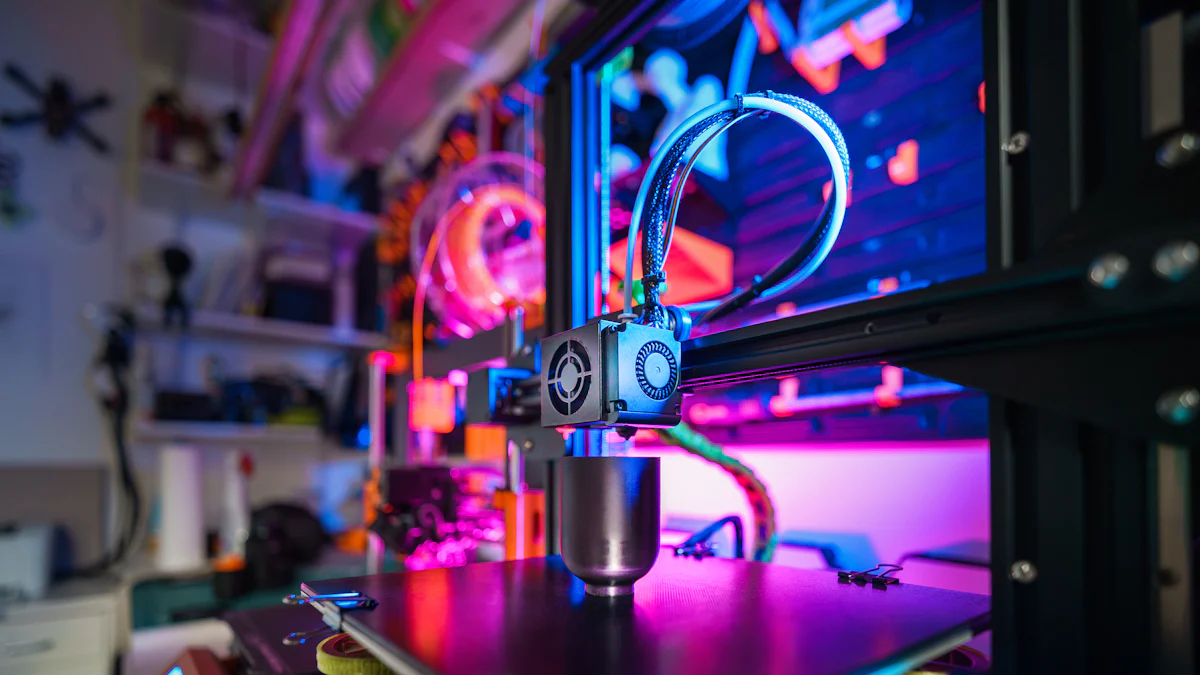

The rise of 3D printing expands the concept of inkjet printing beyond traditional substrates. You can use this technology to create complex objects, including car parts and biological tissues. Nanographic printing is also gaining traction, utilizing nanopigments to produce high-quality images with less ink. This approach bridges the gap between digital and offset printing, offering you a versatile solution for diverse applications.

Challenges and Opportunities for the Industry

The inkjet printing industry faces several challenges, particularly in regulatory compliance. Food packaging regulations targeting PFAS chemicals require manufacturers to adapt their processes. Similarly, the textile industry must address environmental concerns, creating opportunities for eco-friendly ink solutions and waste reduction through direct-to-garment printing.

In the pharmaceutical sector, compliance with the Drug Supply Chain Security Act drives demand for efficient tracking solutions. These challenges present opportunities for innovation, allowing you to develop compliance-focused products and sustainable practices. By addressing these issues, the industry can unlock new potential and maintain its growth trajectory.

The Potential for Growth and New Applications

The inkjet printing market is poised for significant growth, driven by advancements in technology and increasing demand for high-quality images. You can now achieve near-offset quality on inkjet presses, opening doors to applications like catalogs and magazines. Packaging has emerged as a key target market, with digital label printing and on-demand fulfillment aligning with sustainability goals.

Inkjet printer applications continue to expand, particularly in sectors like textiles and packaging. Its precision and flexibility make it ideal for short-run processes where customization is essential. As technology improves, you can expect even greater versatility, enabling new applications and driving innovation across industries.

Inkjet printing has evolved into a sophisticated technology, offering sharper print quality and higher resolutions through advancements in printhead design. Modern printers dynamically adjust droplet sizes, producing photorealistic images and crisp text. Enhanced ink chemistry has expanded the color gamut, enabling vibrant and durable prints across diverse media.

The versatility of inkjet technology has transformed industries. Retrofitting inkjet systems onto existing presses improves efficiency and reduces waste. In fashion, it enables intricate patterns and personalized designs. In pharmaceuticals, it ensures precise dosage creation. From art reproductions to customizable decor and packaging, inkjet printing continues to redefine creative possibilities.

Future innovations promise even greater potential. You can expect eco-friendly inks, smart ink technology, and applications in flexible electronics. The ability to achieve near-offset quality and explore new markets ensures inkjet printing remains a dynamic force in modern industries.

FAQ

What makes inkjet printing different from traditional printing methods?

Inkjet printing stands out for its precision and versatility. Unlike traditional methods, it applies ink directly to the substrate without requiring plates. This approach reduces waste and allows you to print on diverse materials, including paper, fabric, and ceramics. It also supports customization and short-run production.

Can inkjet printers handle large-scale industrial applications?

Yes, modern inkjet printers are designed for industrial use. They excel in packaging, textiles, and electronics manufacturing. High-speed models with advanced printheads ensure efficiency and quality. You can rely on them for tasks like circuit printing, personalized packaging, and large-format textile designs.

Are eco-friendly inks as effective as traditional inks?

Eco-friendly inks deliver comparable performance to traditional inks. Options like water-based and soy-based inks provide vibrant colors and durability. Algae-based inks even offer a negative carbon footprint. These sustainable choices allow you to achieve high-quality results while reducing environmental impact.

How does inkjet printing support customization?

Inkjet technology enables variable data printing, allowing you to personalize content like labels, direct mail, and promotional materials. It also supports intricate designs on textiles and decor. This flexibility ensures that your projects meet specific requirements without compromising quality or efficiency.

What industries benefit the most from inkjet printing?

Industries like fashion, medicine, electronics, and packaging benefit significantly. You can use inkjet printing for tasks like creating custom textiles, producing 3D-printed medical devices, manufacturing flexible circuits, and designing vibrant packaging. Its adaptability makes it a valuable tool across diverse sectors.