Basic Definition

Invisible Ink is an ink that, after being processed with a special formula or technique, is invisible under normal light and requires specific conditions such as lighting, temperature, chemical reagents, etc. to develop. Its core function lies in concealed information transmission, combining fun, security, and anti-counterfeiting.

Core principles

-

Invisible ink achieves the “invisible developing” effect through the following methods:

-

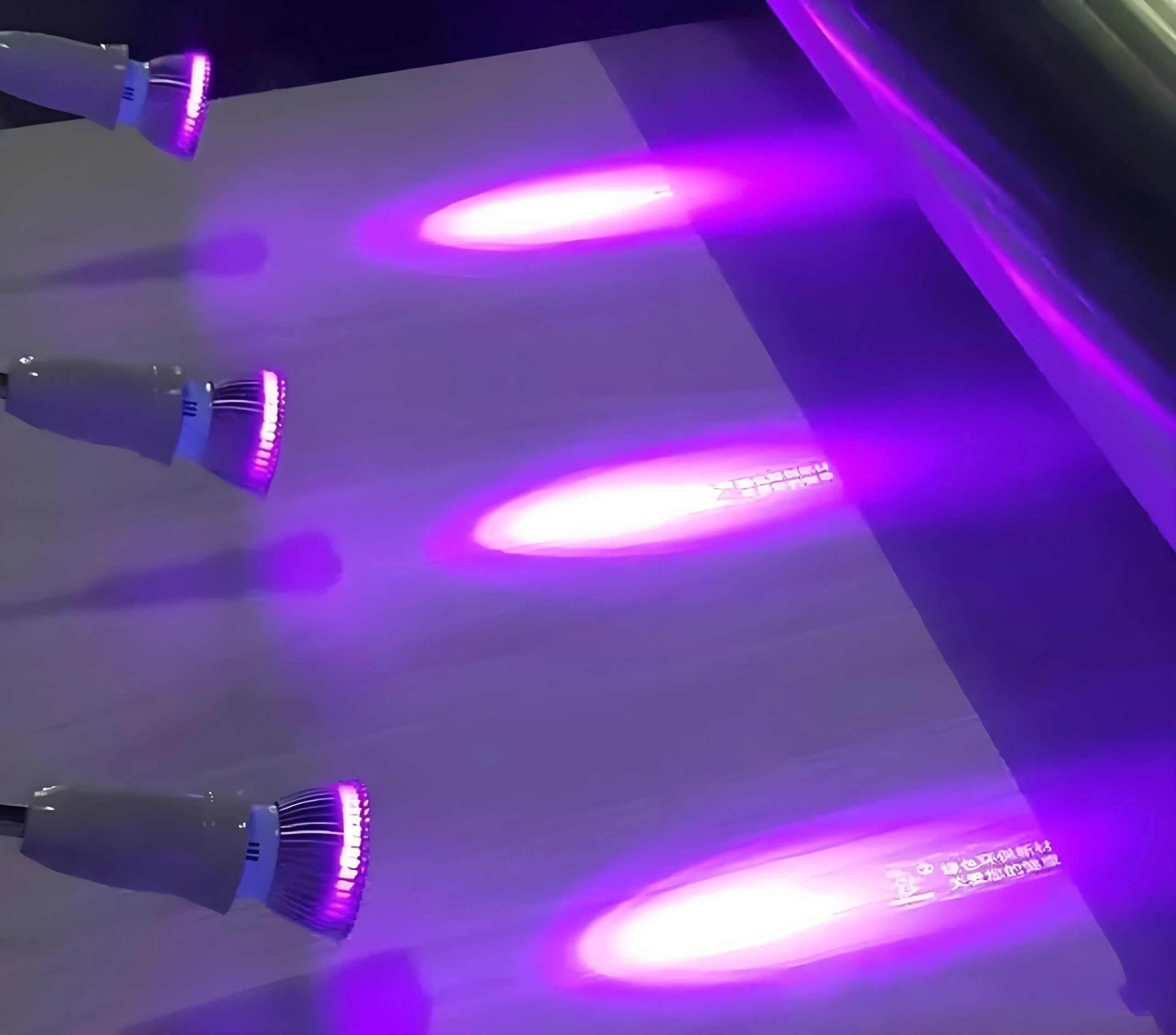

Photoluminescence: such as ultraviolet (UV) fluorescent ink, which absorbs UV light and emits visible light.

-

Thermal reaction: Oxidation or chemical changes occur after heating, resulting in color development (such as phenolphthalein turning red when heated with alkali).

-

Chemical development: Reacting with specific reagents (such as iodine, soda water) to produce colored substances.

-

Microcapsule technology: Encapsulate color developing components, rupture and develop under pressure or friction.

Application Fields

-

Anti counterfeiting and security:

-

Invisible markings (such as UV fluorescent coding) on banknotes, passports, and receipts.

-

Product packaging anti-counterfeiting labels require specialized equipment to verify authenticity.

-

Confidential communication:

-

The seamless transmission of military and commercial confidential documents, and the destruction without leaving any trace after development.

-

Education and entertainment:

-

DIY scientific experiments for children (such as lemon juice thermal ink), puzzle game props.

-

Artistic Creation:

-

Invisible painting or hidden information design, combined with interactive visualization to enhance the experience.

Precautions for use

1. Development condition control:

-

UV ink needs to match the corresponding wavelength (such as 365nm/395nm) to avoid development failure caused by mismatched light sources.

-

The development temperature of thermal ink needs to be precise, as excessive temperature may burn the carrier (such as paper).

2. Carrier adaptability:

-

Different materials (paper, plastic, fabric) have significant differences in ink adhesion and development effect, and need to be tested in advance.

3. Safety and Environmental Protection:

-

Some chemical inks contain irritating ingredients and should be operated in a well ventilated environment to avoid contact with the skin.

-

It is recommended for children to choose non-toxic formulas (such as food grade lemon juice, milk).

4. Persistent maintenance:

-

UV ink may gradually degrade when exposed to sunlight for a long time and needs to be stored away from light.

-

Avoid unexpected development or failure caused by high temperature and high humidity environment.

Market and Trends

-

Driven by anti-counterfeiting demand: With the increase of counterfeit goods, the application of invisible ink in packaging and document fields is growing rapidly.

-

Intelligent upgrade: Develop intelligent invisible ink that can be remotely recognized by combining nanotechnology or electronic tags.