material summarization

Rubber UV Printing

Rubber is an excellent material in UV printing. The ink cures rapidly on the rubber substrate when exposed to ultraviolet light, thus obviating the need for lengthy drying times and speeding up production cycles. Provides quality printing with sharp and vibrant colors and the most intricate graphics. This printing method is widely used to print logos, graphics, text, or intricate designs directly onto rubber products of all kinds. Rubber UV printing inks are specially developed with unique additives to ensure proper adhesion to varying surfaces of rubber, hence providing strong bonding and preventing peeling. They can be applied to a wide range of rubber materials, having varying degrees of softness; properly cured UV inks are resistant to abrasion, fading, and weathering.

Why Choose us

Our Advantages

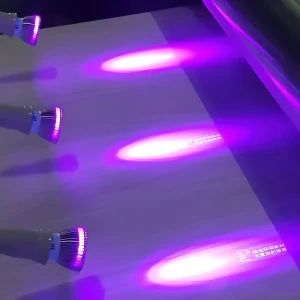

UV Curing Mechanism

The ink is cured rapidly when it is left in the ultraviolet light, turning hard at once. Hence, there is no long curing time, thus providing quick production cycles.

Wide Application

Our Rubber UV Printing Solution can print logos, graphics, text, or any complex design directly onto various rubber products, such as silicone wristbands, rubber seals, and medical components.

High Print Quality

We provide crisp, bright colors and high-resolution prints on rubber media.

Fast Production

Printing on rubber is quick and economical due to the energy-absorbing actions of UV inks.

Special Ink Formulation

Particularly special additives have been used in the formulations of inks for proper adhesion to the rubber non-porous surface, enabling strong binding and the prevention of peeling.

Products Can Be Used for this material

Related Products

Application Solution

Related Solutions

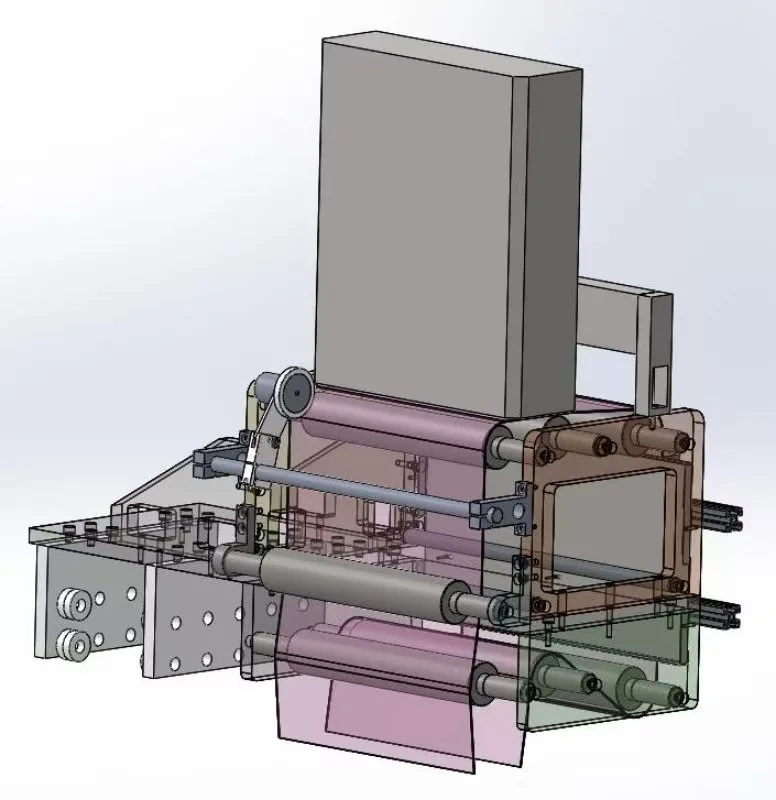

Inline UV Printing Solution

This Inline solution, UV Rubber printing is configured to use industrial inkjet printers that can achieve long-lasting and abrasion-resistant prints on rubber products in a production line. When high-speed customization can be done without loss of print quality.

Sticker

UV printing is perfect for rubber materials, especially stickers. With physical properties going hand in hand: elasticity and resistance of rubber to UV inks, rubber can be used as raw material for stickers because of their better quality. The ink is properly adhered in the UV-curing process since other inks would smear or fade. Thus, rubber stickers can be used indoors or outdoors.

Label

UV Printing on rubber materials, especially for labels, is performed with versatile UV inks, which cure quickly under UV light to provide durable and scratch-resistant prints. This method is ideally applied for creating vibrant label designs, which don’t go bad in wearing environment.

Container Lid

In Container Lid UV Printing Solution, Rubber UV ink is applied to print on plastic lids to enable adhesion through unique additives. The special ink cures instantly through UV light’s patented formula, giving durable, crisp branding on the lids.

Bag

UV printing on rubber is perhaps the most innovative for bag manufacture. It provides a durable and abrasion-resistant print on rubber portions of the bag to be used in addition to making the bag visually appealing and long-lasting. This technique does well with every bag fabric; therefore, it helps maintain flexibility and design diversity in bag production.

Bottle

UV printing on rubber materials, such as those used in bottle manufacturing, offers versatility and durability. Outstanding images can be printed directly onto rubber surfaces using easily suitable UV printing devices, making the aesthetic of the bottle remarkably beautiful without adding on a label.

Find Printing Content

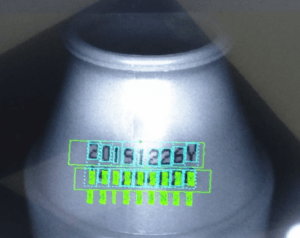

Codes And Logo UV Printing

UV Printing Codes

This makes use of special inks and is applied on rubber substrates. This technique is a secure printing process using invisible codes that show only when the rubber is placed under UV light. Main features entail high-security against counterfeits, instant ink cure to avoid lengthy production processes, and ais apparent in the varied print possible: barcodes and QR codes.

UV Printing Pattern & Text

Pattern and Text Printing by Rubber UV Printing is a specialized process involving the curing of inks with ultraviolet (UV) light onto rubber surfaces for maximum detailed and durable prints. This method yields instant drying, high-quality prints with brilliant colors, and is versatile to print some designs. The specially formulated ink adheres to rubber surfaces well without peeling-off or breaking the bond. Being eco-friendly, there are no persistent organic pollutants (POPs) or dangerous gases emitted in the working process.

you may want to know