material summarization

Plastic UV Printing

Polymer-based options are some of the most common materials within UV printing. UV is a digital printing method whereby ultraviolet light cures the wet ink. The printing process involves creating artwork on a computer, and a printer then jets UV ink onto the plastic substrate in tiny drops. The UV light then cures the ink immediately, eliminating the need for a lengthy drying process. The printed image has good and durable quality, resisting fading, scratching, and water damage. UV printing on plastic is widely used for signage, branding logos, and other promotional products. It has remarkable versatility with excellent printed results.

Why Choose us

Our Advantages

Superior Plastic Printing Quality

Our Plastic UV Printer delivers exceptional print quality on plastic surfaces, ensuring sharp and vivid images.

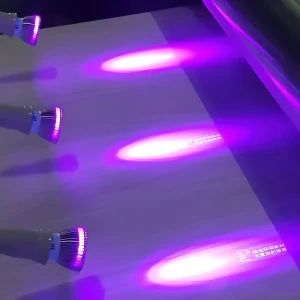

Fast Drying on Plastic

The UV curing technology allows for rapid drying, minimizing production time and increasing efficiency.

Exceptional Adhesion to Plastic

The ink adheres strongly to the plastic, preventing peeling and ensuring long-lasting prints.

Versatile Plastic Printing Options

It can handle a wide range of plastic substrates and print designs with precision.

Durable Plastic Prints

The prints are highly resistant to scratches, fading, and chemical exposure, maintaining their quality over time.

Products Can Be Used for this material

Related Products

Application Solution

Related Solutions

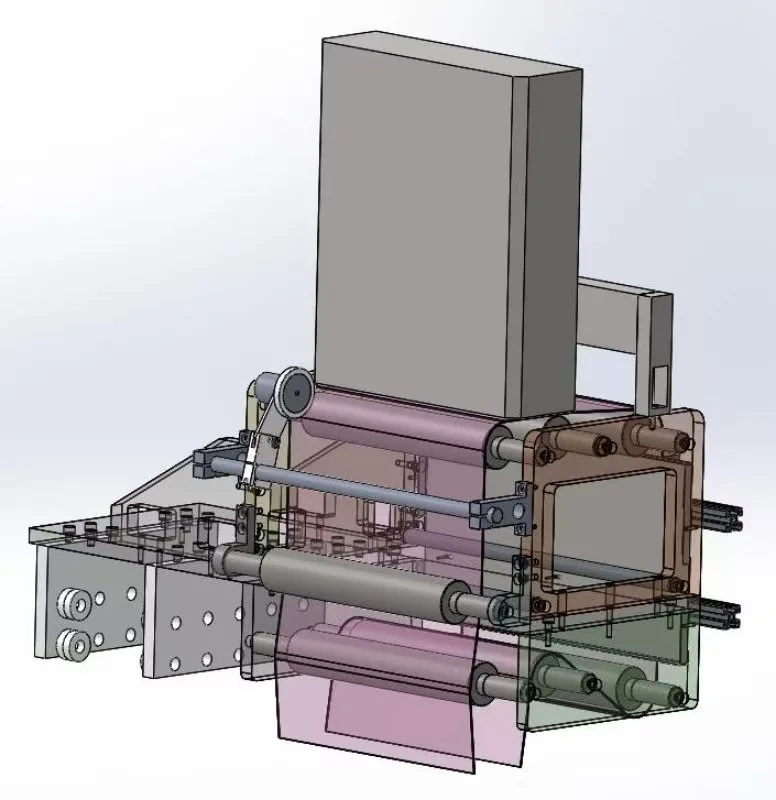

Inline UV Printing Solution

UV printing on plastic in an Inline solution incorporates direct jetting of UV inks onto plastic surfaces and curing with UV light, resulting in a durable and high-quality finish for various marketing materials. This process promotes efficiency and is waste-reducing, as it permits on-demand printing without pre-printed materials.

Sticker

Based on UV printing material plastic, ABS plastic is suggested for its durability and flexibility. UV printing on plastic stickers gives them brilliant colors that resist fading; hence they can be used outdoors for a long time in branding.

Label

UV printing on plastic labels makes it an exceptionally durable, high-quality finish with bright colors and vivid features. Fast production due to the quick-dry ink would be useful for many applications.

Box

UV printing on plastic is an ideal technique for producing durable and vivid labelling and decoration on boxes. This is done with the aid of UV ink that dries immediately under UV light, thus providing a finish that is both scratch-proof and water-resistant. This method is especially successful when used for branding and product preservation; also, it is a quick and economical approach for manufactures when creating boxes.

Container Lid

In terms of UV printing on plastic, especially container lids, high-quality, durable graphics enhance resistance against scratches and fading. It applies UV light to cure inks instantaneously, making it the fastest and most efficient process requiring very little dry time.

Cup

When UV printing on plastic cups, the technology helps in printing directly vibrant, UV-cured inks on the surface of the cup. This yields high-resolution, durable graphics that are perfect for custom branding and designs. In addition, the quick printing time and less waste make this an efficient personalized cup printing choice.

Card

UV printing on plastic cards ensures great versatility and durability. The UV ink coating on the plastic is instantly cured when placed under UV lamps, giving it scratch and water resistance. In this way, one creates colorful business cards that remain longer.

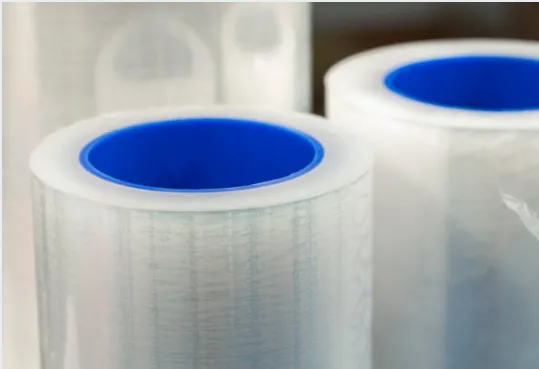

Roll Film

UV printing on plastic, especially roll film applications, is an exciting new process for the high-quality, durable graphical prints. Such printing is done for color images right onto the rolls of plastic sheets for purposes ranging from packaging to signage to decoration. Plastic also allows easy integration with roll-to-roll printing systems, making it an efficient and versatile medium for production.

Bag

This is an ideal process to perform UV printing on plastic for bag production, offering vivid and long-lasting designs. Using UV light, the ink is cured directly onto the plastic bags, ensuring its water resistance and scratch-proof graphics. It’s one of the best methods to obtain branding and long-lasting product packaging.

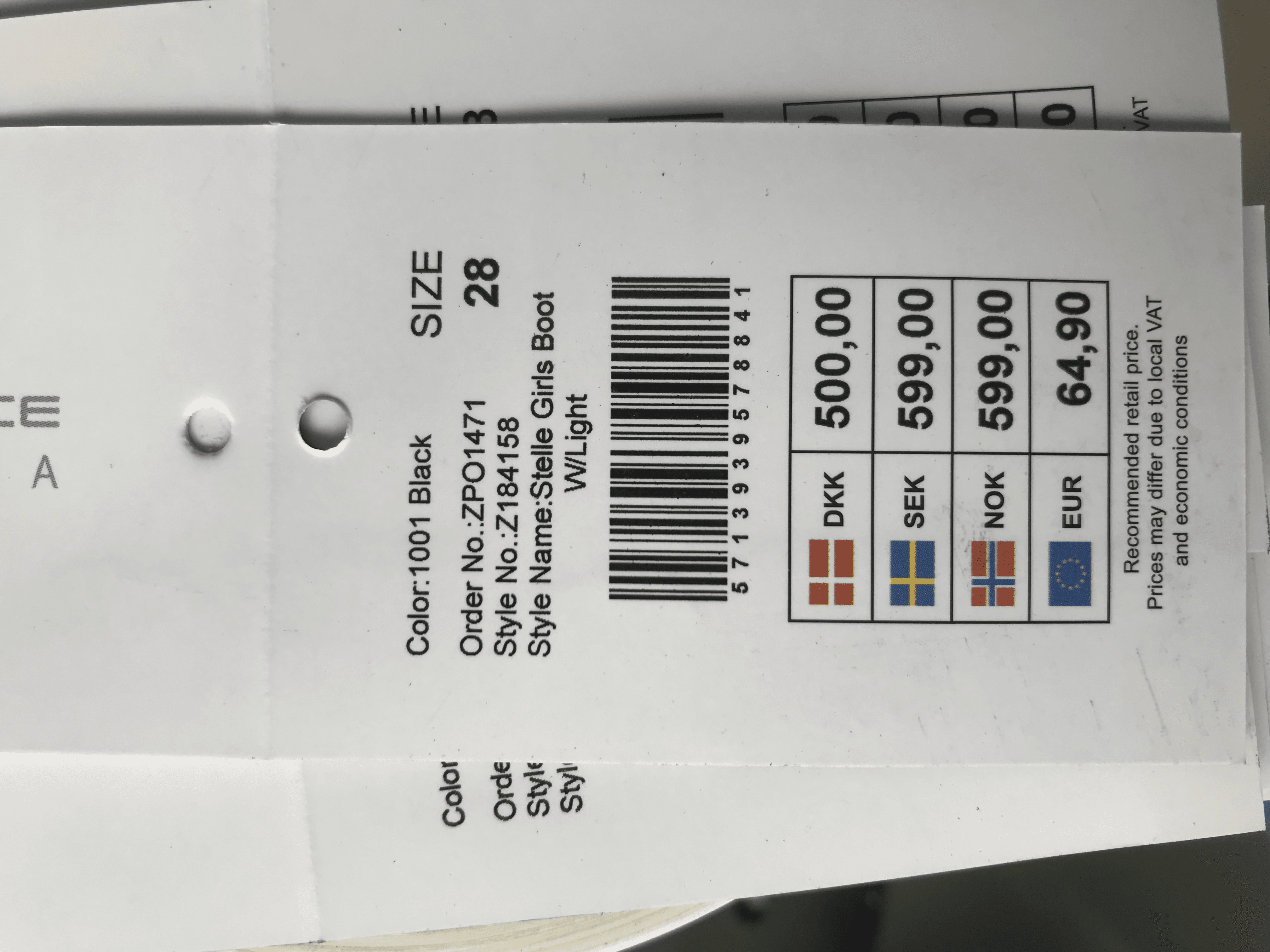

Tag

UV printing on plastic supplies a highly durable and vibrant option for producing tags. The process jets UV ink onto plastic that is bent under UV light and immediately cured, providing the tags with water, fade, and scratch resistance. This technique is perfect for creating durable, high-quality tags for branding and identification purposes.

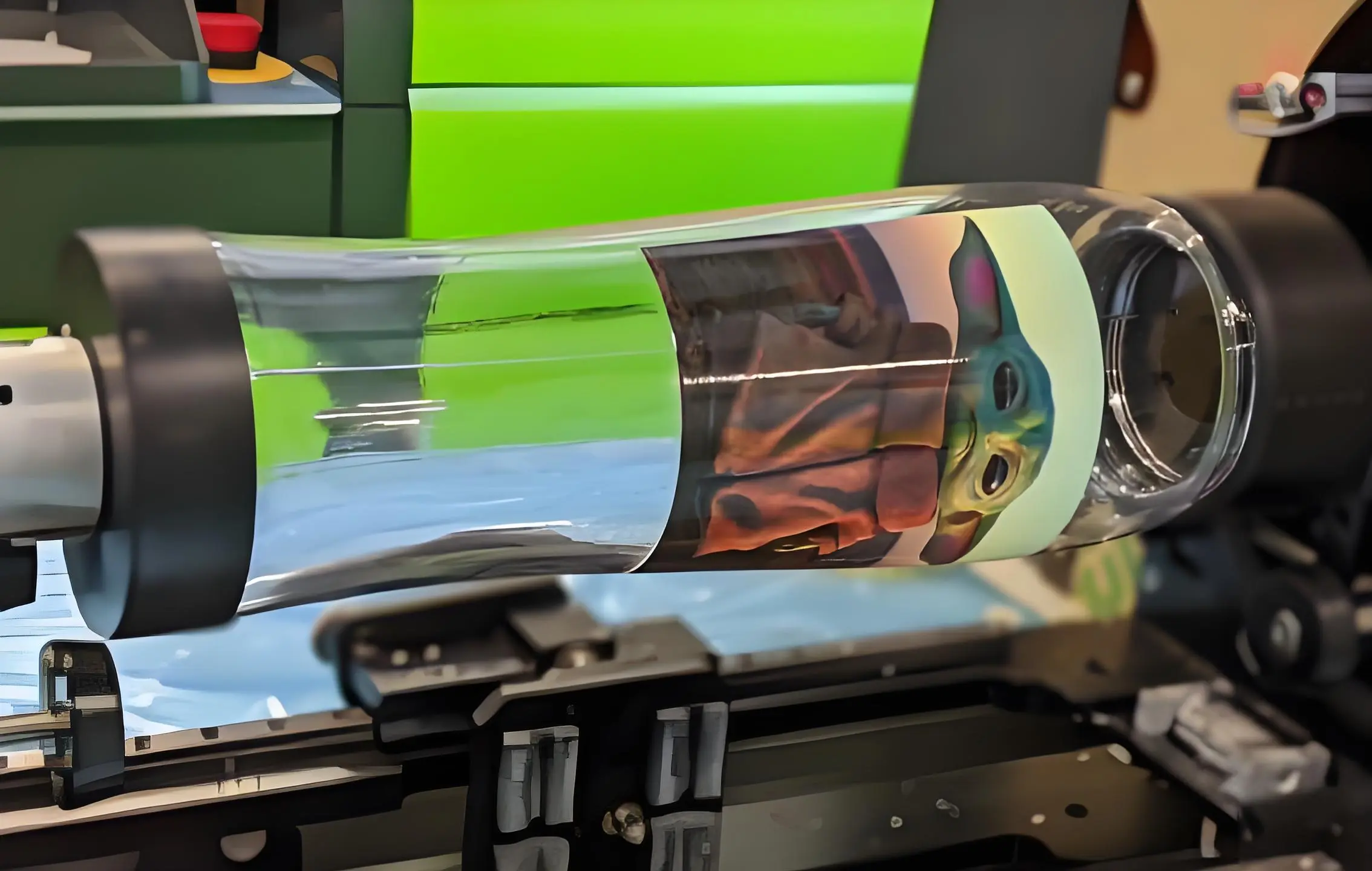

Bottle

It is the process of UV printing of plastics, used for bottle applications. Here, bright and durable graphics are applied to the surface of plastic bottles. The process virtually jets UV inks and cures them instantly by means of UV light, thus providing a high-quality scratch-resistant finish.

Find Printing Content

Codes And Logo UV Printing

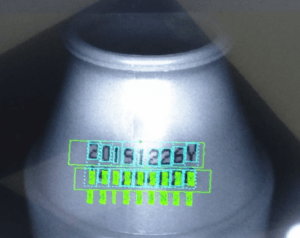

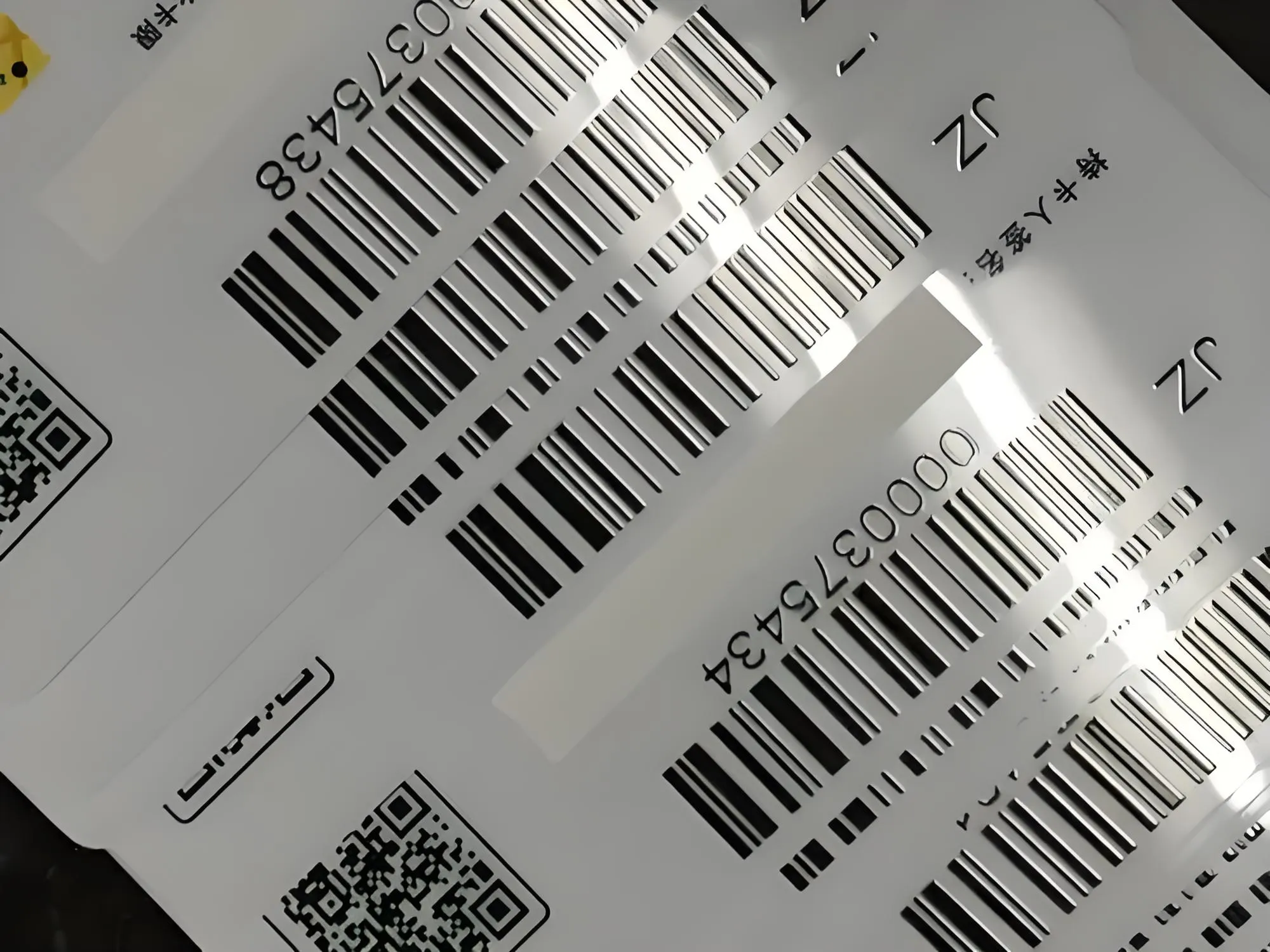

UV Printing Codes

Plastic UV printing provides Code Printing with several coding possibilities, including barcodes, QR codes, and alphanumeric codes. This method employs UV inkjet printers, which guarantees high-speed printing at printing speeds of 100-200 m/min and 200-600-DPI resolution. The primacy of this design lies in curing with UV technology, which entails immediate drying and efficient printing.

UV Printing Pattern & Text

This prints digital UV ink onto plastic to create Pattern & Text. It is very scratch and water-resistant, can handle full-color images and special effects, and can work on various materials. Artwork is created, and a machine jets droplets of UV ink; they instantly cure when exposed to UV light, resulting in outstanding, highly detailed Pattern & Text Printing that won’t fade. This process is great for signs, branding, and marketing goods and shows a good versatility in Pattern & Text Printing applications.

you may want to know