material summarization

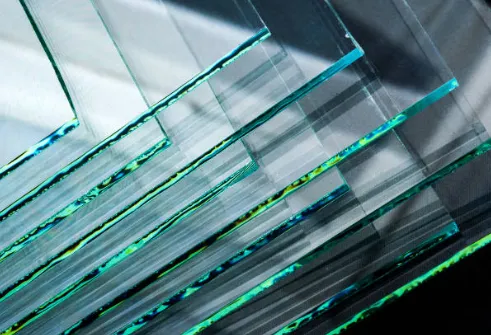

Glass UV Printing

Glass is one of the most common for coatings in UV printing. It refers to full-color image printing with UV ink using a UV light. Also known as UV pinning, this assures that the ink lies firmly on the glass. Its salient features include:

•High quality: Produces bright, well-detailed, and long-lasting images.

•Versatile: In addition to glass, it can also be applied to plastic, paper, and metals.

•Eco-friendly: Energy-efficient and almost zero VOC structures.

•Personalized: Permits personalized high quality on the object.

•Customizable: It can be used for short-runs and quick customization.

Why Choose us

Our Advantages

High-Quality Printing

UV-printed glass is characterized by glossy, detailed, long-lasting images. UV ink is a special formulation that, when subjected to UV light, executes color polarization most optimally.

Versatile Application

All the materials can be UV-printed: both flat and cylindrical surfaces: glass, plastics, papers, and metals. There are also options on the market that handle photo and color.

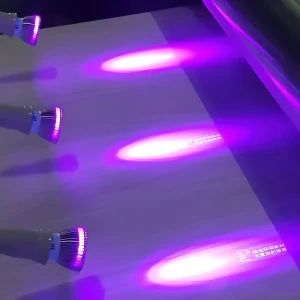

Eco-Friendly Process

UV Printing requires less energy and releases almost no VOCs.

Personalized Options

High-quality personalization is achievable for items, resulting in customers with unique products all bearing their design.

Adhesion Assurance

The glass surface is generally pre-treated before printing to maintain ink adhesion. Test adhesion post-printing to check the quality of the print.

Products Can Be Used for this material

Related Products

Application Solution

Related Solutions

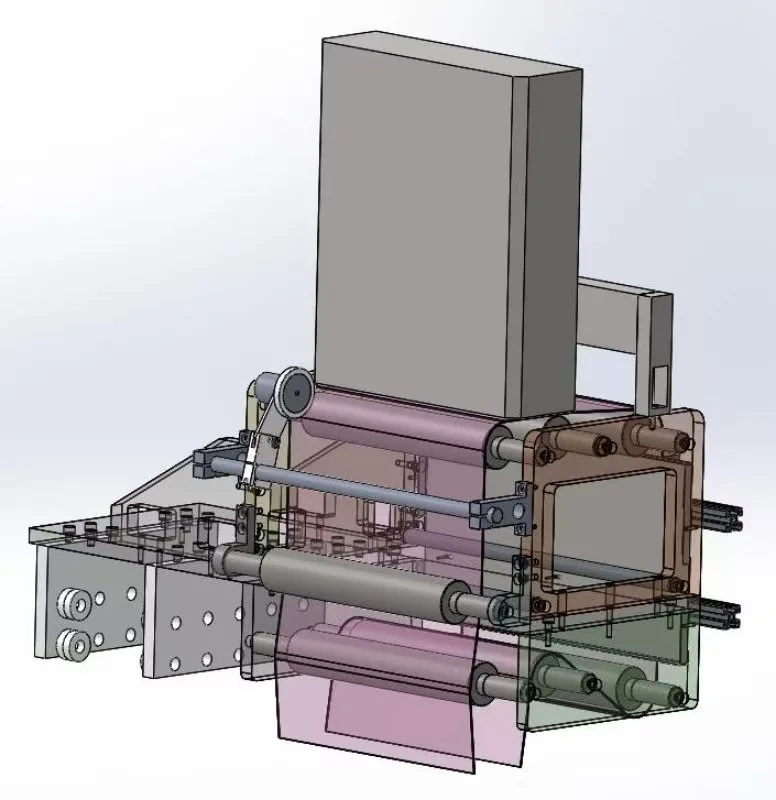

Inline UV Printing Solution

You can print on glass using Inline solutions that use the special process where a continuous movement of glass is passed through a device, thereby granting them great production efficiency with value-for-money and quality of direct printing on the product. Apart from that, this method guarantees perfect bonding and durable finishes; this is also well suited for a wide range of applications.

Container Lid

UV printing utilizes UV-cure inks that bond to glass surfaces to produce durable and high-quality designs on container lids. This method is a good way of creating branding and ensuring the longevity of the print on the container lid.

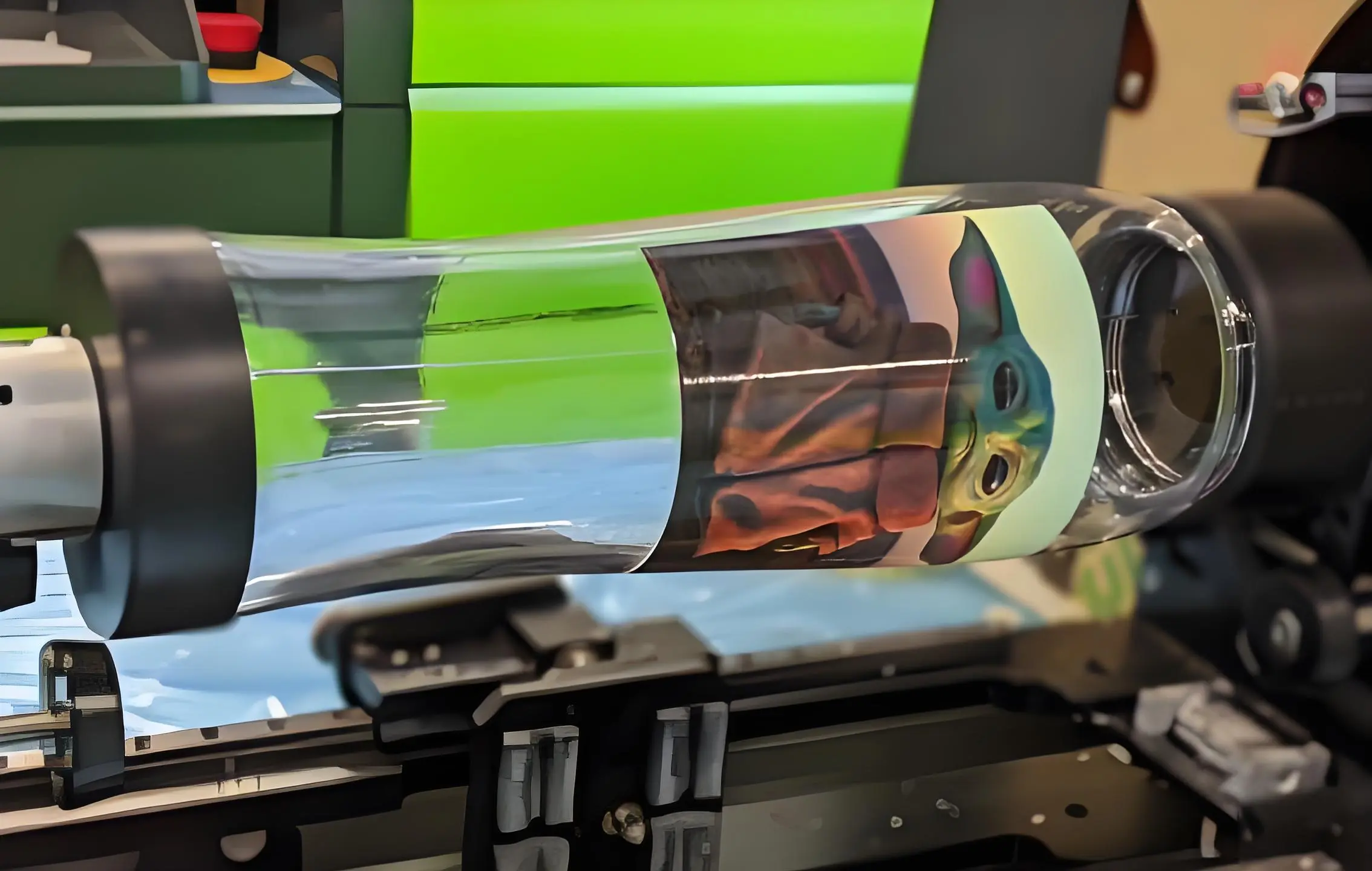

Cup

UV printing employs UV-curable inks applied directly to glass surfaces, which are pretreated beforehand to ensure adhesion. The ink cures instantaneously under UV light, producing durable, colorful designs.

Bottle

UV printing intelligently uses specialized UV-curable inks which are bonded directly to the glass surface following a pre-treatment such as flame treatment. This process allows the design of vibrant and full color designs of high resolution directly on the bottle’s container without the need for additional labeling, and so it enhances the visual pleasure and distinctiveness of the bottles across many industries.

Find Printing Content

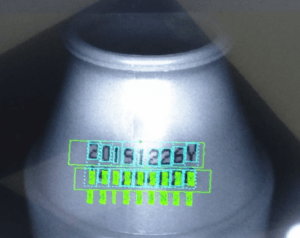

Codes And Logo UV Printing

UV Printing Codes

Code printing is a type of UV printing wherein ultraviolet ink is used to print codes like barcodes, QR codes, or serial numbers. Such codes may remain invisible until exposed to UV light, providing extra security against counterfeit activities. The invisible ink, visible only under UV light, is a key feature in security applications aimed at forgery prevention.

UV Printing Pattern & Text

Pattern and Texture Printing with Glass UV Printing involves using UV ink and light to print directly onto glass surfaces. This technique gives rise to bright and detailed images and text and is instantly dry and environmentally friendly. The process can be applied variably for different materials, allowing inexpensive personalization in superior quality.

you may want to know