material summarization

Fabric UV Printing

Textiles are one of the main materials to opt for, alongside fabrics, in UV printing. Fabric UV printing refers to a process in which ultraviolet light cures the ink instantly, resulting in colourful and vivid prints that will last longer. The use of UV-curable inks means it could be finished rapidly since these inks cure in seconds once exposed to UV light and the actual process of printing includes a digital printing process where the designs are printed onto a transfer film using a UV printer. The printed design is then heat-pressed onto the fabric. Many benefits accrue from this process. There will be vivid prints and sharp detail, suitable for a wide variety of fabric, including cotton, polyester, nylon, and blends. Perhaps UV inks are durable, resistant to fading and washing, and allow for quick turnaround times in printing.

Why Choose us

Our Advantages

High-Quality Prints

The Fabric UV Printing process ensures sharp details and vibrant colors due to the precise ink deposition.

Versatility

It can be used on a variety of fabrics, including cotton, polyester, nylon, and blends.

Durability

The UV-cured inks are resistant to fading and washing, ensuring long-lasting prints.

Fast Turnaround

The quick printing and curing process allows for rapid production, meeting tight deadlines.

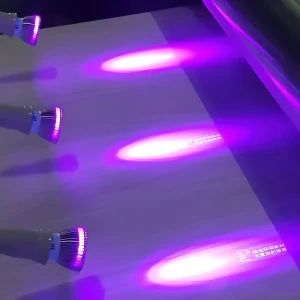

Specialized Inks

The UV-curable inks rapidly solidify when exposed to UV light, enabling quick drying times.

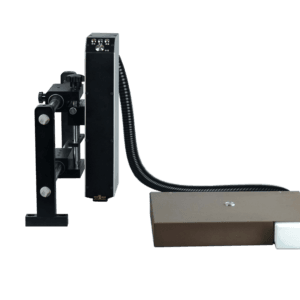

Digital Printing Process

Designs are printed digitally onto a transfer film using a UV printer, ensuring accurate and consistent results.

Products Can Be Used for this material

Related Products

Application Solution

Related Solutions

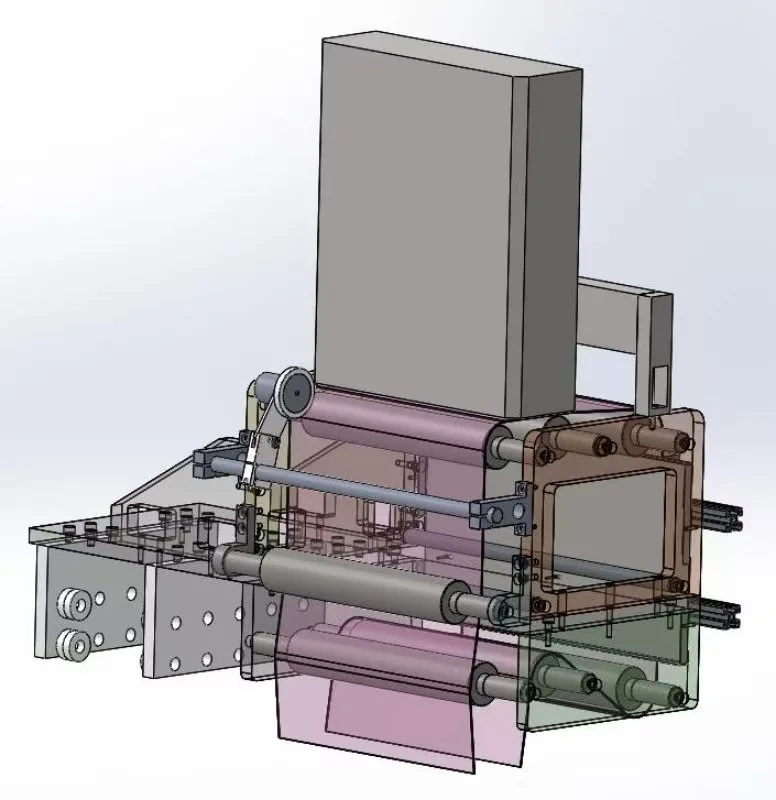

Inline UV Printing Solution

In the Inline UV printing solution for fabric, fabrics are fed directly into the printer for continuous, high-speed printing. This method is ideal for mass production, ensuring consistent and vibrant prints on textiles.

Sticker

UV printing on fabric is associated with the rustic art of sticker creation. A colorful and durable image printed on the fabric surface sticks wonderfully onto it. It is a terrific material to make custom stickers with a long-lasting finish that does not fade and wears well.

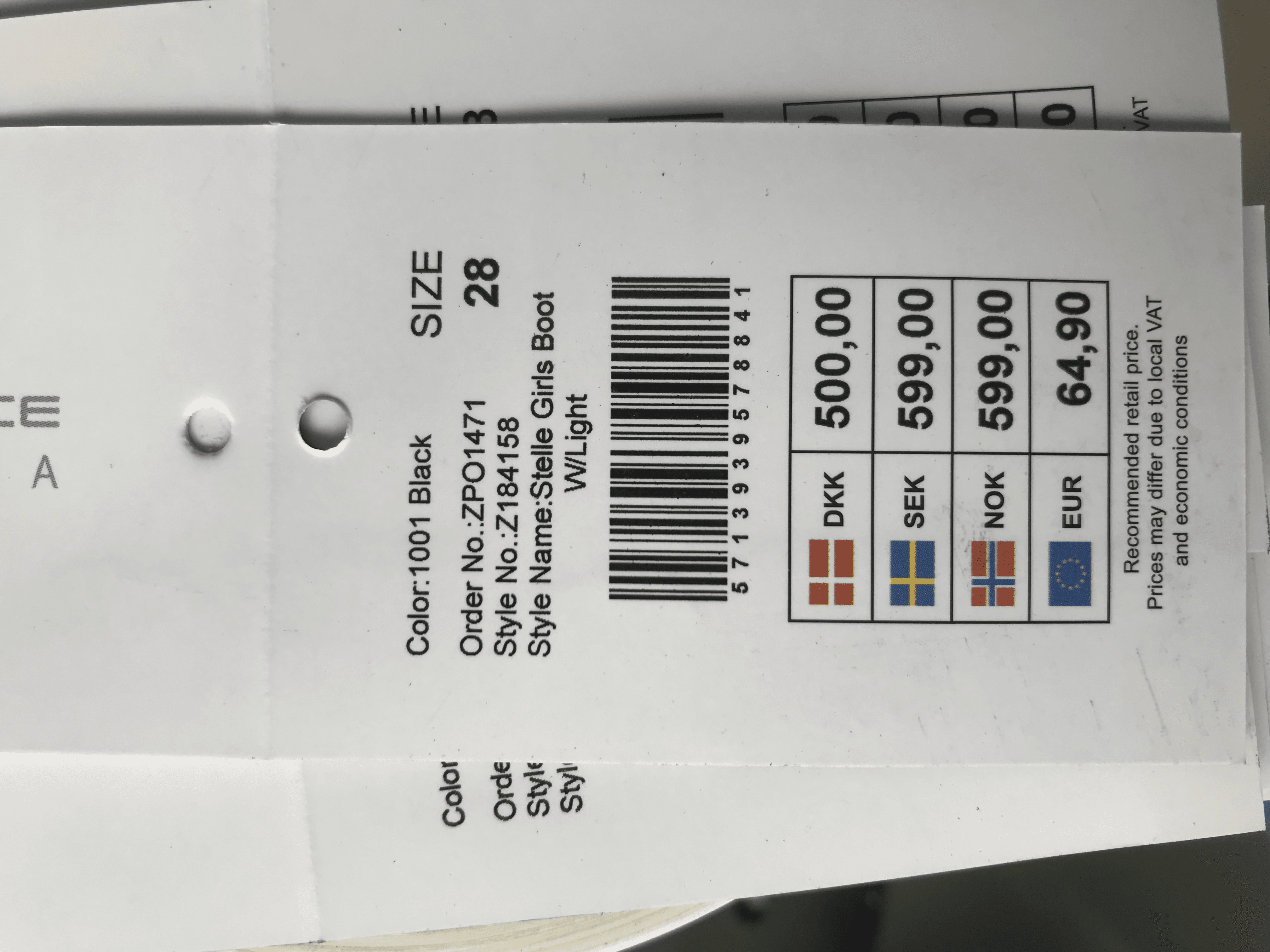

Label

UV printing on fabric brings high-quality labels within reach, with all the colors and sharpness. This method affords durable and non-fading labels which increase product awareness and visibility. Labels made are versatile depending on what type of fabric to use.

Bag

UV printing on fabric is used in bag production for projecting bright and durable prints directly on the fabric surface, enhancing bag aesthetics and durability. This allows for great detail and colorfastness on various bag materials; fabric UV printing ensures quick turnaround times in bag manufacturing.

Tag

UV printing tagged with fabric utilizes the application of vivid UV curing inks onto all substrates of tags while providing quick dry time and durable prints. The method is compatible with a number of tag substrates with guaranteed quality and durability results.

Find Printing Content

Codes And Logo UV Printing

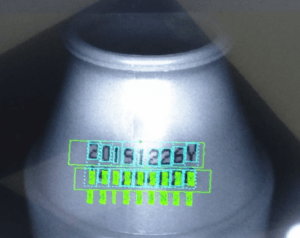

UV Printing Codes

Code UV printing is a more advanced method of printing by utilizing UV ink to create unique codes, such as barcodes, QR codes, or serial numbers. These unique markings are completely invisible under ordinary light and become visible under UV light, thus greatly augmenting security against counterfeiting and allowing product traceability.

UV Printing Pattern & Text

Pattern & Text Printing with Fabric UV Printing uses ultraviolet light to dry the ink directly on the fabric, allowing for bright and long-lasting prints. This process gives high-quality details, instant drying, and versatility to handle different fabrics.

you may want to know