Application We Solved

Hardware Tools Marking

solution summarization

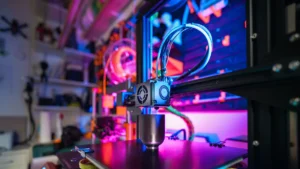

Hardware Tools Marking Description

Our advanced inkjet printing technologies deliver precision, durability, and efficiency for hardware tools marking. Utilizing UV Inkjet Printers, we enable high-resolution coding on diverse materials (metal, plastic, composites) with instant UV-cured inks, ensuring smudge-proof, weather-resistant logos, serial numbers, or safety labels. For high-speed applications, Thermal Inkjet (TIJ) Printers offer quick-drying, non-contact printing ideal for intricate graphics or small text on tools, packaging, or components. Both solutions support permanent, chemical- and abrasion-resistant marks critical for traceability, branding, and compliance. Customizable integration with production lines ensures seamless operation, reducing downtime. Eco-friendly inks and low maintenance designs align with sustainable manufacturing goals. Trust our expertise to elevate your tool marking quality and productivity.

Why Choose us

Our Advantages

Wide Range of Applications

Our UV and Thermal Inkjet printers seamlessly mark on metals, plastics, composites, and coated surfaces, accommodating everything from rugged wrenches to precision drill bits. This versatility ensures consistent quality across diverse hardware tools, regardless of material hardness or texture.

Industrial-Grade Durability

UV-cured and thermal inkjet marks resist chemicals, abrasion, and extreme environments, critical for tools exposed to oils, solvents, or outdoor conditions. Serial numbers on steel parts or safety labels on power tools remain legible throughout their lifecycle, ensuring compliance and traceability.

High-Speed, Non-Contact Precision

Thermal Inkjet technology delivers micron-level accuracy on delicate or uneven surfaces (e.g., screwdriver handles, micro-components) without physical contact, eliminating tool damage. Ideal for high-volume production lines requiring rapid, error-free coding.

Customizable Automation Integration

Our printers integrate with robotic arms, conveyors, or ERP systems, enabling real-time variable data marking (batch codes, QR codes) for Industry 4.0-ready manufacturing. Minimize manual intervention and adapt to dynamic production needs effortlessly.

Sustainable Efficiency

Low-energy UV lamps, recyclable printheads, and solvent-free inks reduce waste and carbon footprint. Achieve eco-certifications while maintaining high throughput—perfect for brands prioritizing green manufacturing.

Products Can Be Used In This Solution

Related Products

materials to be printed on

Related Inkjet Printing Materials

Plastic

UV inkjet printers excel on smooth/glossy plastics (ABS, PC) for high-contrast logos on tool housings, resisting oil and UV fading. TIJ suits porous/textured surfaces (nylon handles) with fast-drying inks for safety labels. Both ensure chemical-resistant, durable markings critical for power tools and measurement devices in harsh environments.

Rubber

Flexible UV inks stretch on silicone/EPDM grips (pliers, anti-vibration mounts), resisting deformation. TIJ prints non-smudge safety warnings on porous rubber mats using quick-penetrating inks. Both maintain clarity despite frequent friction or chemical exposure in tool handling.

Metal

UV-cured inks bond instantly on stainless steel/aluminum tools (wrenches, drill bits), surviving abrasion and solvents for permanent serial codes. TIJ delivers non-contact micro-text/barcodes on coated metals for traceability. Ideal for high-speed production lines requiring precision without surface damage.

Ceramic

UV technology etches precise scales/IDs on industrial ceramics (cutting blades) with ceramic-fused inks, enduring extreme heat. TIJ applies temporary batch codes on unglazed surfaces for kiln-fired tools. Combines permanence and flexibility for aerospace or medical tooling.

Glass

UV printers mark tempered glass panels (measuring instruments) with scratch-proof, heat-resistant logos using adhesion-promoting inks. TIJ, with specialized solvents, prints temporary calibration guides on non-porous glass. Ensures readability in high-temperature or sterile industrial settings.

Find Printing Content

Codes And Logo UV Printing

UV Printing Codes

UV and TIJ printers deliver permanent, high-contrast codes (QR/barcodes, batch numbers) on metals, plastics, and ceramics. UV inks withstand abrasion for tool traceability, while TIJ enables non-contact, high-speed serialization on production lines. Critical for compliance, inventory control, and anti-counterfeiting in industrial tool manufacturing.

UV Printing Pattern & Text

UV printers produce intricate logos, safety icons, or multilingual text on rubber grips or glass panels with vibrant colors and weather resistance. TIJ excels in fine text (<0.5mm) on uneven surfaces (tool handles) using fade-resistant inks. Ensures branding clarity and instructional durability in harsh environments.