Application We Solved

Container Lid

solution summarization

Container Lid UV Printing Description

The UV printing solution for container lids is a specialized system, where UV lights print designs directly on lids made of plastic. UV curing technology boasts speed and efficiency with minimum drying time, thus enabling high-quality, durable graphics that adhere excellently to the surface of the lid. This solution is designed to print on the various plastic substrates most often used in container lids, including PET, PP, and PVC with sharp, vibrant color, and intricate detail. The technology is often used in the direct printing of logos, barcodes, expiry dates, and other product information on container lids.

Why Choose us

Our Advantages

High-Quality Printing

Container Lid UV Printing Solution provides a great print quality. It uses ultraviolet light to print the design directly on the plastic container lids with great clarity and durability. With this, high-resolution graphics are then printed that highlight the product's visual appeal.

Fast and Efficient Process

With UV curing technology, the ink dries instantly, minimizing drying time. This leads to a rapid and efficient printing process, allowing for increased productivity and shorter turnaround times.

Durable Graphics

Prints made by this solution are highly durable. They adhere to the lid surface very well, thereby securing the graphics against the wear and tear of an operational environment and providing a long-lasting and clearly visible brand identification.

Versatile Design Options

Our system allows for a wide range of design possibilities. Whether it’s complex patterns or simple logos, we can bring your creative ideas to life on the container lids.

Environmentally Friendly

UV printing is an eco-friendly option as it consumes less energy and produces less waste compared to traditional printing methods. It aligns with our commitment to sustainable practices.

Products Can Be Used In This Solution

Related Products

materials to be printed on

Related Materials

Plastic

Some kinds of plastics include PET, PP, and PVC; the substrate for UV printing on caps can be versatile in quality. They provide a high degree of quality and reliability, producing sharp colors and designs that will resist fading and scratches.

Metal

Metal materials, especially suitable for UV printing solutions on container lids, provide durability and high-resolution prints. They present a robust surface for branding, ensuring their longevity and resistance to wear.

Rubber

Rubber is indeed the perfect material for container lids - flexible, durable, and non-porous. Container Lid UV Printing Solution introduced the UV ink and bonded it very well to the rubber surface to provide bright, durable prints that can withstand abrasion and environmental degradation.

Ceramic

Ceramic is a solid and heat-resistant material for container lids. In UV printing, it gets vibrant and long-lasting graphics resistant to pressure, assuring brand visibility and protecting product safety.

Glass

Glass material in Container Lid UV Printing Solution offers exceptional durability and high-resolution prints. It’s chemically resistant and provides a sleek, premium finish to lids with vibrant, UV-cured inks.

Watch the videos to see how it works

Related Videos

Find Printing Content

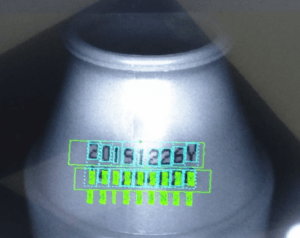

Codes And Logo UV Printing

UV Printing Codes

Code Printing with Container Lid UV Printing Solution involves utilizing UV light to directly imprint codes onto plastic lids, ensuring quick-drying ink for efficient, high-quality coding. Key features include UV curing technology for instant ink drying and durability of imprinted codes on various plastic materials.

UV Printing Pattern & Text

Pattern & Text Printing with Container Lid UV Printing Solution utilizes UV light to directly print sharp, durable designs and text onto plastic lids. Key features include instant UV curing, high print quality, and eco-friendliness. This method ensures vibrant patterns and texts with minimal drying time.

you may want to know