Application We Solved

Bottle

solution summarization

Inkjet Bottle Printer Description

The Bottle UV Printing Solution is an excellent set mechanism. It employs ultraviolet (UV) light to directly print designs on glass or plastic bottles. This method enables full-color, high-resolution graphics that stick on the bottles with no need for separate labels. The major facets of Bottle UV Printing are essentially direct print: a design actually applied directly on bottle surface; high-quality color graphics with intricacies of detail and bright distinct colors. It has a large range of applications for printing on all types such as water bottles, wine bottles, and cosmetic containers. Bottle UV Printing allows fast curing and customization; thereby creates an efficient and personalized way to decorate bottles.

Why Choose us

Our Advantages

Wide Range of Applications

This solution applies to any bottle shape, be it a water bottle, a wine bottle, or a cosmetic container, allowing greater flexibility in catering to the diverse demands of different industries.

Fast Curing

With UV inks that rapidly harden when exposed to UV light, our printing solution enables quick production, saving time and increasing efficiency.

Customizable Designs

We offer the ability to create personalized designs with gradients, textures, and variable data, giving your bottles a unique and eye-catching appearance.

Direct Printing

Unlike traditional labels, our UV printing applies the design directly onto the bottle surface, ensuring a seamless and high-quality finish.

High-Quality Graphics

The technology we use enables intricate details and vibrant colors, making your bottle designs stand out with exceptional clarity and visual appeal.

Specialized Equipment

Our solution includes a specialized UV printer, UV-curable inks, and a rotary jig to ensure precise and full wrap-around printing on cylindrical surfaces.

Products Can Be Used In This Solution

Related Products

materials to be printed on

Related Inkjet Printing Materials

Plastic

Plastic materials used in Bottle UV Printing Solutions are versatile and durable. The UV printing process provides direct surface application of high-quality graphics onto plastic, allowing for a brightly colored yet scratch-resistant finish.

Rubber

Among rubber surfaces, such as silicone, especially shine in Bottle UV Printing Solution with their ability to produce high-quality long-lasting prints directly on surfaces.

Metal

Mostly recyclable metal materials in the range of bottle UV printing solutions are known for their durability and consequently sleek appearance. Stainless steel, aluminum, or even iron have become the material choices for such long-lasting, high-quality prints.

Ceramic

Ceramics in the Bottle UV Printing Solutions assure sustainability and a luxurious finish. With their UV-setting inks, the designs become water-proof while also scratch resistant, making ceramist a favored material for bottle decoration of the highest quality.

Glass

The glass material allows a bottle UV printing solution great durability with excellent image quality. Eco-friendly solution; low VOC and works for almost all bottle types. The UV curing process makes for quick production and allows for detailed design customization.

Watch the videos to see how it works

Related Videos

Find Printing Content

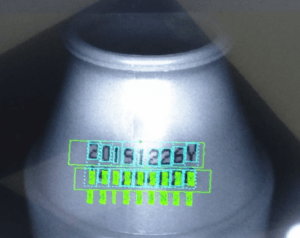

Codes And Logo UV Printing

UV Printing Codes

Bottle UV printing solution involves direct application of designs on the surfaces of bottles using UV light, promising high-quality graphics in a short turnaround time. Some of that include direct printing, high-quality graphics, and UV curing that allows instant ink drying.

UV Printing Pattern & Text

Print pattern and textual contents directly onto bottles with the use of specialized UV inks and printers. The method provides high-quality graphics, instant-dry performance, and highly durable resistance against fading and scratching. Customization generally allows for various codes and alphanumeric details printed right onto the bottle’s surface.

you may want to know