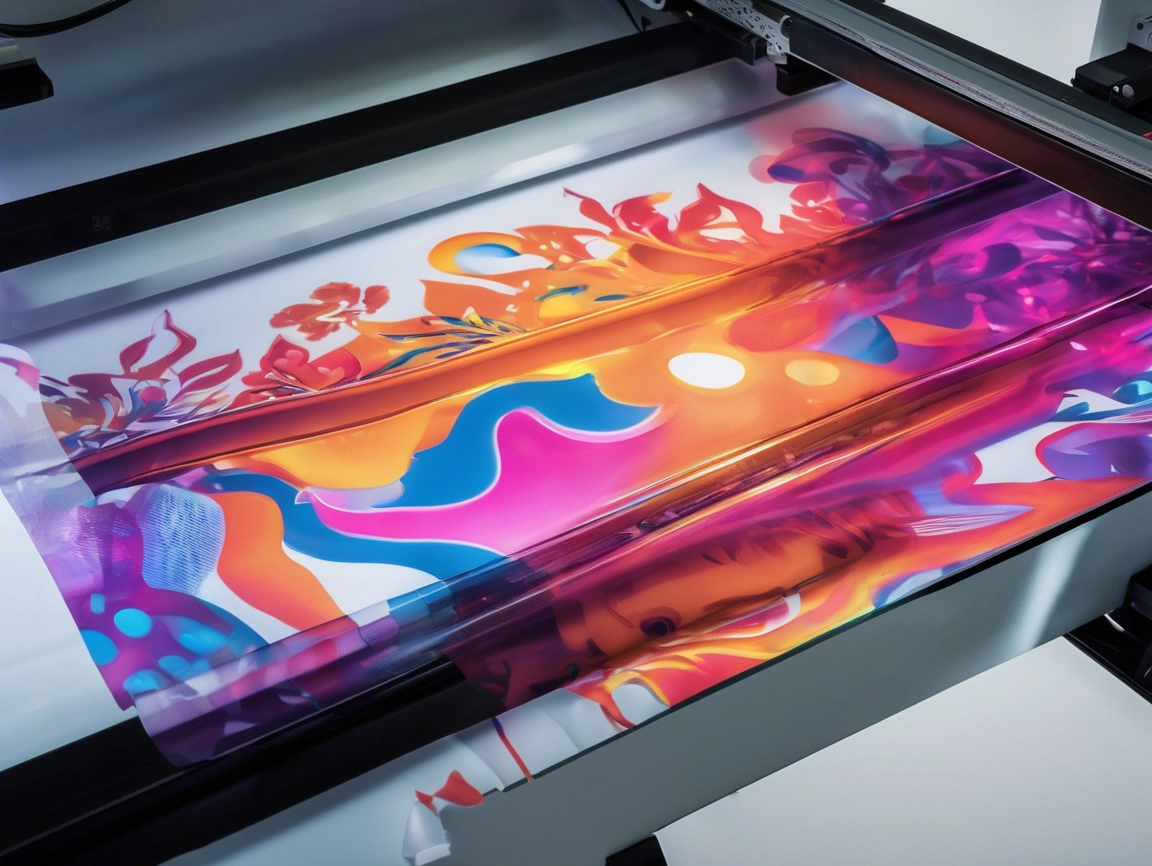

The printing industry has undergone a revolutionary transformation with the advent of UV printers. Unlike traditional printing methods, UV printing leverages advanced technology to deliver unparalleled precision, durability, and versatility. As businesses increasingly demand high-quality, customized prints on diverse materials—from glass and metal to plastics and wood—UV printers have emerged as a game-changer. This article explores the mechanics, applications, and advantages of UV printers, providing actionable insights for businesses considering this technology.

A UV printer is a digital printing device that uses ultraviolet (UV) light to instantly cure specially formulated inks onto surfaces. Unlike conventional printers, UV printers can print on virtually any material, produce vibrant colors, and create durable, scratch-resistant finishes.

To fully grasp the value of UV printers, it’s essential to dive into their technical workings, industry-specific applications, and comparative advantages over traditional methods. Below, we break down the critical aspects of UV printing, supported by data-driven insights and real-world use cases.

1. How Does a UV Printer Work?

UV printers operate by depositing UV-curable inks onto a substrate and instantly curing them with ultraviolet light, creating a hardened, durable layer.

UV printing combines digital precision with chemical innovation. The process begins with the printer applying UV-reactive inks to the target material. These inks remain in a liquid state until exposed to UV light emitted by integrated LED or mercury-vapor lamps. The light triggers a photomechanical reaction, transforming the ink into a solid polymer within milliseconds.

Key components of a UV printer include:

- Print Heads: Precision nozzles (e.g., Epson, Ricoh) that control ink droplet size.

- UV Lamps: High-intensity light sources for rapid curing.

- Ink System: Resin-based inks containing photoinitiators.

Traditional solvent-based inks require hours to dry, limiting production speed. UV curing eliminates drying time, enabling immediate handling and stacking of printed items. This efficiency is critical for industries like packaging, where high throughput is essential.

Understanding the mechanics of UV printing sets the stage for exploring its real-world applications. Let’s examine how industries leverage this technology to solve unique challenges.

2. Key Applications of UV Printers Across Industries

UV printers are used in signage, packaging, automotive, electronics, and interior design for printing on materials like acrylic, metal, ceramics, and textiles.

The versatility of UV printers makes them indispensable in multiple sectors:

A. Signage and Advertising

- Billboards: Weather-resistant prints for outdoor use.

- Retail Displays: High-gloss finishes for POP (point-of-purchase) displays.

B. Packaging

- Custom Labels: FDA-compliant inks for food packaging.

- Luxury Boxes: Metallic and textured effects for premium branding.

C. Automotive and Electronics

- Dashboard Panels: Scratch-resistant instrument clusters.

- Circuit Boards: Conductive ink printing for prototypes.

Comparative Table: UV Printing vs. Screen Printing

| Factor | UV Printing | Screen Printing |

|---|---|---|

| Setup Time | Minutes (digital files) | Hours (screen preparation) |

| Material Range | Unlimited (3D objects included) | Limited to flat surfaces |

| Durability | 5+ years outdoors | 2–3 years |

The broad applicability of UV printers stems from their technical advantages. Next, we’ll analyze how they outperform traditional printing methods.

3. Advantages of UV Printing vs. Traditional Methods

UV printing offers faster production, eco-friendly operations, superior durability, and compatibility with 3D surfaces.

Speed and Efficiency

- Zero Drying Time: UV-cured prints are ready instantly, reducing bottlenecks.

- Single-Pass Printing: Achieves full-color prints in one cycle, cutting labor costs.

Environmental Benefits

- Low VOC Emissions: UV inks contain no volatile organic compounds, complying with EU regulations.

- Energy Savings: LED UV lamps consume 70% less power than mercury-vapor alternatives.

Quality and Versatility

- Vivid Colors: Pigment-rich inks achieve 98% Pantone matching.

- 3D Effects: Raised textures (e.g., braille, embossing) for tactile finishes.

Case Study: Furniture Manufacturing A European furniture brand reduced waste by 40% using UV printers to apply finishes directly onto MDF boards, eliminating paint overspray.

To maximize these benefits, businesses must select the right equipment. Let’s explore key purchasing criteria.

4. How to Choose the Right UV Printer for Your Business

Select a UV printer based on print width, ink types, substrate compatibility, and software integration.

Critical Factors to Consider

- Print Area: Flatbed printers handle rigid materials (e.g., 4′ x 8′ sheets), while hybrid models print on curved objects.

- Ink Options:

- Hard Inks: For rigid surfaces like glass.

- Flexible Inks: For textiles and leather.

- Software: RIP (Raster Image Processor) compatibility for color management.

Cost Comparison: Entry-Level vs. Industrial UV Printers

| Feature | Entry-Level (20k–20*k*–50k) | Industrial (100k–100*k*–300k) |

|---|---|---|

| Speed | 10–20 m²/hour | 50–100 m²/hour |

| Resolution | 720–1440 dpi | 2400 dpi |

| Warranty | 1 year | 3–5 years |

Once a printer is selected, proper maintenance ensures longevity. Let’s discuss upkeep strategies.

5. Maintenance and Cost Considerations

Regular nozzle cleaning, UV lamp replacement, and ink system maintenance are critical to sustaining print quality.

Maintenance Checklist

- Daily: Clean print heads and check ink levels.

- Monthly: Inspect UV lamps for intensity drop.

- Annual: Replace mechanical parts (e.g., belts, rollers).

Cost Breakdown

- Ink Costs: 100–100–300 per liter.

- Energy Consumption: 500–500–1,200/year for LED systems.

- Downtime Losses: Poor maintenance can cost $5k/day in halted production.

As technology evolves, UV printing continues to innovate. Let’s glimpse into its future.

6. Future Trends in UV Printing Technology

Emerging trends include AI-driven color matching, hybrid 3D printing, and sustainable ink formulations.

Innovations to Watch

- AI Integration: Automated color correction for reduced waste.

- 3D Hybrid Printers: Combining additive manufacturing with UV printing.

- Bio-Based Inks: Soy and algae-derived resins for carbon neutrality.

Market Growth Forecast The global UV printer market is projected to grow at 9.8% CAGR, reaching $15.7 billion by 2030 (Source: Grand View Research).

Conclusion

UV printers redefine industrial printing by merging speed, quality, and adaptability. From creating eye-catching signage to durable automotive components, their applications are limitless. Businesses investing in UV technology gain a competitive edge through faster turnaround times, reduced waste, and premium output. As advancements like AI and eco-friendly inks emerge, UV printing will remain at the forefront of digital manufacturing.

Ready to explore UV printers for your business? Contact our experts for a tailored solution that aligns with your production needs.